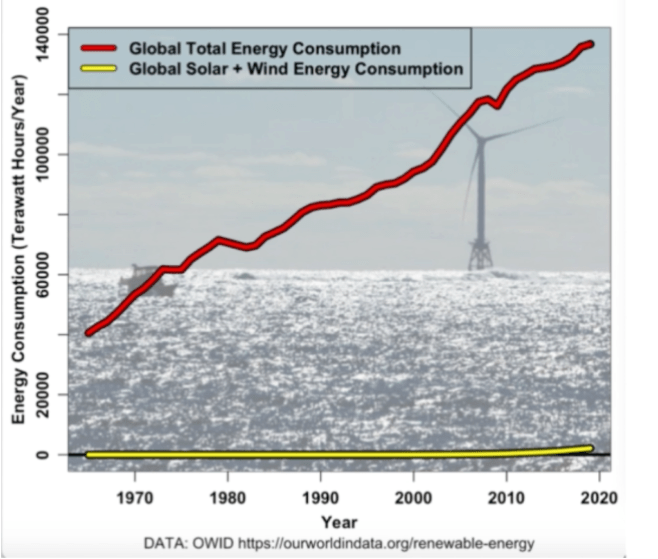

It has been forecasted that the U.S. needs about 125 GW of new electricity generation capacity by 2030 and about 600 GW of new generation capacity by 2050. The combined maximum manufacturing of new nuclear, new wind and new solar cannot provide this growth in time. Previously written here, here and here. The Our World in Data graph showing worldwide capacity of total primary energy by sources shows the futility of expecting the new Demand for energy to be supplied from wind and solar.

The graph above illustrates the dismal contribution of wind and solar to the total Primary Energy needs of the world. Bjorn Lomborg (and others) has written numerous articles that document the poor capacity factor, high cost and unreliability of wind and solar after decades of spending billions.

The answer to providing the needed Primary Energy for electricity generation over the next twenty five years is to build more dispatchable electricity generation capacity from new natural gas, nuclear and coal plants. We need to build lots of new gas, nuclear and coal plants. Easy to write, harder to accomplish. That is the purpose of this article, to try to quantify the colossal design, manufacturing and construction supply-chain effort that needs to be accomplished on a fast-track basis.

New Generation Capacity Manufacturing Supply-Chain

The gas turbine supply-chain limitation was covered in my previous article here and by POWER Magazine here. Nuclear is the fuel that provides the largest carbon free capacity today and it is likely to be the fuel of choice in the future. However, building 125 GW of new electricity generation capacity by 2035 or so could with a Herculean effort be accomplished with new coal plant construction. This is about the same as the electricity generation capacity that has been shut down since 2010. The previous article discussed the 151 new coal plants that were planned in 2008 most of which were never built. Between now and 2035 we need to build the coal plants that were planned in 2008 and were never built.

The Coal Plant Supply-Chain That Was circa 1975-1980

In 1975 I was a project engineer for the startup and improvements for the 720 MW Roxboro Generating Station Unit #3. The superheater needed to be replaced with upgraded alloy due to design issues of temperature and steam distribution throughout the over 1500 individual flow circuits. The tubing material selected was 304H stainless steel. Over twenty miles of new tubing needed to be fabricated into 48 superheater assemblies, each comprised of 26 tube circuits about 120 feet long. The contract was signed about March of 1975 for delivery to site and installation in the fall outage the same year. The tubes had to be manufactured from stainless steel billets, drawn into tubing and the tubing bent, attached together into assemblies, stress relived in a furnace and welded together. The total superheater required dozens of truck loads for delivery from Chattanooga to Roxboro. The same project today would be possible but not in the same time frame. It will require more than a year or two to simply fabricate a superheater of this size and get it delivered. Much of the tubing and components would be sourced from Asia.

Remembering Combustion-Engineering

Let’s discuss Combustion-Engineering’s Chattanooga works in 1975. Here is an aerial picture of this magnificent facility.

The facility was over 88 acres under roof and included capabilities for manufacturing steel tubing, waterwalls, heavy walled headers, fabrication of tube assemblies as described above for the Roxboro superheater and also nuclear reactors and steam generators. I intentionally used the adjective magnificent to describe it. Here is a quote from my friend Tom who worked at C-E during this time period:

“I did a stint at CE in Chattanooga and still vividly recall the enormity of the manufacturing capability. For instance 15,000 ton press that could bend 12” thick steel Into a cylinder for a completed nuclear vessel weighing 700 tons.

A Gang drill setup to drill 1600 holes through a 26” Inconel tube sheet for nuclear PWR steam generators.

1000 ton crane to handle these fabrications and heat treat furnaces large enough to stress relieve them before shipment. What an experience to view and work with these marvels.”

The facility evolved and progressed over many years to become the pearl of manufacturing prowess that it was in 1975. Combustion-Engineering in these times was capable of producing steam generators that could power about 25,000 MW of electricity generation capacity each year. The business volume in 1977 dollars was about $1 Billion/year. The manufacturing volume was almost equal to the business profits of aftermarket maintenance and repairs. Being outstanding in design, manufacturing and services was a huge business for tens of thousands of employees. In 1978 Combustion-Engineering was # 125 on the Fortune 500 list of companies. Two competitors during this era with facilities similar to Combustion-Enegineering were Babcock & Wilcox and Foster-Wheeler. B&W was # 132 on Fortune’s list and Foster-Wheeler # 207.

Today Combustion Engineering and Foster-Wheeler U.S. shops are gone, B&W’s downsized but, thankfully, still in operation.

Today I discussed a replacement/repair of a high pressure header for a Utility coal steam generator in Texas. I was told the header is on emergency order and it will be on site this fall. The header is sourced from somewhere in Asia and welding of tube studs and completion of fabrication will be done in South Carolina. This is bout 24 weeks lead time for just one header. I described a 1350 MW steam generator in a previous article, here. Just to show a rough idea of the immensity of a large coal steam generator. The one described is the B&W Zimmer Plant, supercritical steam generator. In electricity generation capacity, it is nearly twice the size of Roxboro Unit #3.

How About Talent?

I was watching Mike Rowe on TV yesterday and he stated that today over 485,000 manufacturing jobs remain unfilled. Tens of thousands of highly skilled craftsmen such as the Boilermaker/Welders such as those shown below are needed. But, the training and education of the workforce is a topic for another day. Here is a recent WSJ article on building the craft workforce.

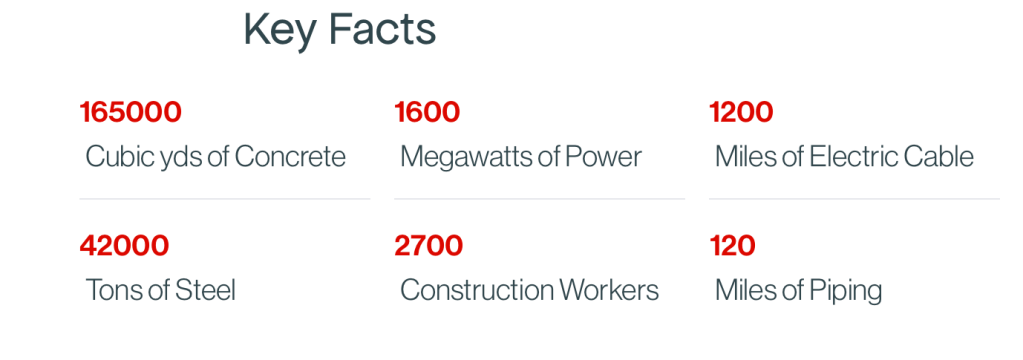

Building a new 1600 MW Coal Plant

One of the most recent coal plants built is the Prairie States Energy Center in southern Illinois. The plant construction is well documented by Bechtel and Prairie States. Here are some statistics to explain the immensity of the challenge of building a plant such as the Prairie States Energy Campus.

Now do the math. It will take about 78 new coal plants like Prairie States to produce 125,000 MW of electricity. Using the proportions of what it took about 13 years ago to build the Prairie States Energy campus would extrapolate to:

- 12,870,000 yards of concrete

- 3,276,000 tons of steel

- 210,600 construction workers

- 93,600 miles of electric cable, mostly copper

- 9,360 miles of piping

This does not include the engineers and designers to prepare the engineering drawings, the factory personnel such as those once employed at the C-E Chattanooga Works described above or Foster-Wheeler’s Mountaintop Pennsylvania facility. I estimate that over 250,000 new engineers, technicians, craftsmen and other factory workers will need to be trained and employed to accomplish this huge task. Unfortunately, many of the trained and experienced engineers needed are like me and many of my friends, who are now retired. The next generation has a huge job to rebuild the supply-chain.

Conclusions

Needed is 600 GW of new reliable, affordable, dispatchable and preferably, U.S. made generation capacity. Satisfying this demand for new capacity will require more new gas, new coal and new nuclear plants to be built. As discussed above, the new gas turbine manufacturing capacity is at it’s limits and optimistically, about half of the needed 600 GW by 2050 can be provided by G-E, Mitsubishi, Siemens and a few others.

Nuclear today provides about 100 GW of electricity generation. Most of the nuclear plants providing this power were built over 40 years ago. It took over 30 years to build the first 100 GW of nuclear generation and yes, we should proceed full speed ahead on doing so again. All things considered, including manufacturing facilities, talent, forgings, high grade nuclear quality steel production and site construction challenges, doubling the 100 GW of existing nuclear capacity may take another 30 years. America misses both the manufacturing facilities such as C-E Chattanooga and others and the 125 GW of coal plant capacity that also has disappeared.

The solution, in my view, is build more coal plants and build them now. It will be difficult to ramp up the supply-chain, but we should begin ASAP. Building plants like Prairie States takes years. At best, about four years from the start of engineering to the first connection to the Grid and then it usually takes months of debugging and fine tuning to reach the full potential of a new plant.

The Roxboro Generating Station has been mentioned by me in many of my articles and talks. Why? Because I was employed at Roxboro as a field service engineer, senior startup engineer, operations superintendent, maintenance contractor and consultant over a fifty year career. I know (or at least remember it) Roxboro plant very well. A side note, Mr. Mendall Long, one of the Greatest Generation and past Manager of Fossil Plant Engineering told me late in his life, “Lad, you are the only guy I know that made a full career out of working on only three boilers” Mr. Long was referring to the Riley Boilers at Sutton and Roxboro Plants that I did indeed work on (amongst others) over a forty year period during his life-time. We miss extraordinary and courageous engineer/managers like Mr. Long.

Roxboro has a capacity of 2,462 MW. I use this plant as an example of the 125 GW’s of new power needed. It will take 50 new plants like Roxboro to produce 125,000 MW’s of coal plant capacity. I described the superheater replacement for Unit #3 above. That is only one unit. Roxboro has four operating units. The Prairie States Energy Campus is a better example because it is newer.

POWER Magazine wrote in October 2013: “The 1,600-MW Prairie State Energy Campus uses the latest coal technology to burn Illinois coal from the Lively Grove mine, located adjacent to the plant. In planning since 2001, the second unit of the two-unit, $4.93 billion plant entered commercial service in November 2012, thus completing the largest coal-fired plant built in the U.S. in 30 years.

The Prairie State Energy Campus (PSEC) is likely the last of the multi-unit coal-fired power plants that will be built in the U.S. in the foreseeable future. The most recently commissioned coal plants (SWEPCO’s 600-MW John W. Turk, Jr. and Duke Energy’s 825-MW Cliffside Unit 6) are single-unit plants with no firm plans for future expansion. The last two-unit coal-fired plants completed as a single project were Luminant’s Oak Grove power plant (2 x 800 MW) and We Energies’ Elm Road plant (2 x 615), both completed in 2010, but that’s where the similarity ends.”

As mentioned above, America should build 78 new plants similar to the Prairie States Energy Campus. We should begin now as the electricity generation crisis is real, not imagined. In 2008 over 150 new coal plants were planned. Most of these were cancelled. That was a mistake that needs to be corrected.

Dick Storm , May 7, 2025

References and for Further Research

- Prairie States Energy Campus Bechtel Statistics: https://www.bechtel.com/projects/prairie-state-energy-campus/

- Wall Street Journal on Workforce Development and Training: https://www.wsj.com/lifestyle/careers/skilled-trades-high-school-recruitment-fd9f8257

- POWER Magazine article on the Prairie States Plant of the Year, October 2013: https://www.powermag.com/prairie-state-energy-campus-washington-county-illinois/

- POWER Magazine on Gas Turbine Supply Crunch: https://www.powermag.com/gas-powers-boom-sparks-a-turbine-supply-crunch/

- Howard Concrete Pumping article on concrete supplied to Prairie States Energy Plant: https://www.howardconcretepumping.com/prairie-state-energy-campus.html

- History of Foster-Wheeler and BHI: http://www.bhifw.com/eng/main/main.html

- FWEC Fortune 500 List #207 1978: https://money.cnn.com/magazines/fortune/fortune500_archive/full/1978/201.html

- Global Energy Monitor on Cancelled Coal Plants: https://www.gem.wiki/Coal_plants_cancelled_in_2008

- How Can a 6,000 MW Utility in 2030 Become a 9,000 MW Utility in 2050 and Still Meet Net Zero Carbon? Update of last year’s article, May 2, 2024: https://dickstormprobizblog.org/2024/05/02/how-can-a-6000-mw-regional-utility-in-2030-which-likely-will-be-a-9000-mw-utility-in-2050-achieve-net-zero-carbon-an-update-on-my-electricity-provider-in-south-carolina/

- NERC Long Term Reliability Assessment Report and including, Data Center Load Growth, December 2024: https://www.nerc.com/pa/RAPA/ra/Reliability%20Assessments%20DL/NERC_Long%20Term%20Reliability%20Assessment_2024.pdf

- Coal’s Final Battle, May 18, 2024: https://dickstormprobizblog.org/2024/05/20/coals-final-battle/

- Tom Shepstone’s Substack repost of Dick Storm commentary, May 20, 2024: https://open.substack.com/pub/energysecurityfreedom/p/why-we-the-american-people-must-win?r=kv1a9&utm_campaign=post&utm_medium=web

- Visualizing 100 Quadrillion BTUs. Shouldn’t Coal Remain in our Energy Mix?” : https://dickstormprobizblog.org/2024/07/02/visualizing-100-quadrillion-btus-of-primary-energy-coal-should-remain-in-our-energy-mix/

- NMA Map of Electricity Prices and coal power in lower 48 states: https://nma.org/wp-content/uploads/2024/02/coal-gen-map-2023.pdf

- WSJ article on “Economic Growth Depends on Electricity, Not Oil”, March 27, 2025: https://www.wsj.com/business/energy-oil/economic-growth-now-depends-on-electricity-not-oil-40250941?st=cbzcRt

- Bjorn Lomberg on the High Cost of Solar and Wind, Climate Change Dispatch, Jan. 2, 2025: https://climatechangedispatch.com/wind-solar-hidden-truth-behind-rising-electric-bills/

- Frazer Institute, “Hot Air, Cold Truths, Bjorn Lomberg, March 2025: https://www.fraserinstitute.org/hot-air-and-cold-truths-bjorn-lomborg

Delaware County Insider, Wind and Solar are Expensive, Bjorn Lomberg, May 24, 2024: https://delawarevalleyjournal.com/lomborg-the-true-cost-of-wind-and-solar-energy/ - Yahoo Finance and National Post, March 2025, Bjorn Lomberg, Wind and Solar are Expensive: https://ca.finance.yahoo.com/news/bjorn-lomborg-solar-wind-power-100008520.html

- Alabama Attorney General is amongst 22 states in appeal to return to coal for power generation revival of the Grid: https://gulfcoastmedia.com/stories/alabama-attorney-general-calls-for-reviving-americas-energy-grid-with-coal,257548?fbclid=IwZXh0bgNhZW0CMTEAAR0XeLob6rYc5WaBBtSyuB7vHctTdzVhTJxJZ96bExtALJBFoqUPAJPKaY0_aem_8TNpNEKQSIdjNrJTJeBF8Q#//

- Life Powered article on the Unreliability of Wind & Solar in Texas, March 29, 2025: https://lifepowered.org/reliability-standards-to-reduce-the-cost-of-wind-and-solar-volatility-in-texas/

- We the People vs. The Ten Headed Swamp Monster : https://dickstormprobizblog.org/2024/07/10/we-the-people-vs-net-zero-indoctrination-by-the-ten-headed-swamp-monster/

- The Magnificent and Indispensable Heat Engines Society Depends on: https://dickstormprobizblog.org/2024/07/30/the-magnificent-and-indispensable-heat-engine-on-which-civil-society-depends-part-1-heat-engines-1-3-million-horsepower/

- The EPA Endangerment Finding Needs to Go! Thomas Shepstone publishing of Dick Storm article, March 9, 2025: https://open.substack.com/pub/energysecurityfreedom/p/the-epa-endangerment-finding-needs?r=kv1a9&utm_campaign=post&utm_medium=web&showWelcomeOnShare=false

- The U.S. Self-Inflicted Electricity Generation Crisis was Created by GONGO the SWAMP Monster, March 19, 2025: https://dickstormprobizblog.org/2025/03/19/the-u-s-self-inflicted-electricity-generation-crisis-was-created-by-gongo-the-swamp-monster-here-is-how-to-end-it/

- Coal Power, It is the End Result that Matters!: https://dickstormprobizblog.org/2025/03/28/coal-power-it-is-the-end-result-that-counts/

- Facing the Hard Truths of Energy, Part 2, The Reality of Replacing Conventional Forms of Energy, Jan. 2024: https://dickstormprobizblog.org/2024/02/06/facing-the-hard-truths-of-energy-part-2-some-facts-on-the-reality-of-replacing-conventional-forms-of-energy/

- Facing the Hard Truths of Energy, Part 3, The Transition that Isn’t, from the perspective of Minerals, Feb. 8, 2024: https://dickstormprobizblog.org/2024/02/08/facing-the-hard-truths-of-energy-part-3-the-transition-that-isnt-from-the-perspective-of-minerals/

- Facing the Hard Truths of Energy, Part 4, The True Agenda for Climate Policies, Feb. 13, 2024: https://dickstormprobizblog.org/2024/02/13/facing-the-hard-truths-of-energy-electricity-generation-and-environmental-protection-part-4-what-is-the-true-agenda-for-climate-policies/

- Energy Matters! March 2024 : https://dickstormprobizblog.org/2024/03/11/energy-matters/

- Update on Hawaii’s “Green New Deal” March 2024: https://dickstormprobizblog.org/2024/03/20/hawaii-a-glimpse-into-the-future-of-the-green-new-deal-aka-inflation-reduction-act-here-is-an-update/

- The Rise and Fall of Nations from the perspective of nuclear power systems manufacturing: https://dickstormprobizblog.org/2023/08/15/the-rise-fall-and-rise-again-of-nations-and-the-realities-of-energy/

- Thomas J. Shepstone posting on Substack of, “Energy Matters If You Value the Life You Now Have and Don’t Want to Live Under Socialism

March 11, 2024: https://open.substack.com/pub/energysecurityfreedom/p/energy-matters-if-you-value-the-life?r=kv1a9&utm_campaign=post&utm_medium=email - Threats to the Electric Grid, March 15, 2024: https://dickstormprobizblog.org/2024/03/15/threats-to-the-grid-electricity-reliability/

Giant Sucking Sound, March 18, 2024: https://dickstormprobizblog.org/2024/03/18/giant-sucking-sound/ - “Update on Hawaii’s Glimpse of the Future of the Green New Deal” March 20, 2024: https://dickstormprobizblog.org/2024/03/20/hawaii-a-glimpse-into-the-future-of-the-green-new-deal-aka-inflation-reduction-act-here-is-an-update/

- The Reality of Electrifying Everything, April 9, 2024: https://dickstormprobizblog.org/2024/04/09/the-reality-of-electrifying-everything-and-the-primary-energy-required-to-generate-the-electricity/

- My Letter to Senator Davis on Coal Power in S.C. April 1, 2025: https://dickstormprobizblog.org/2025/04/03/response-to-palmetto-electric-request-to-contact-our-s-c-senators/

- The Solution to America’s Electricity Generation Crisis: Build New Coal Plants Now! https://dickstormprobizblog.org/2025/04/18/the-solution-to-the-nations-coming-electricity-reliability-crisis-build-new-coal-plants/

- Clean Energy Crisis, May 2, 2025 https://dickstormprobizblog.org/2025/05/02/clean-energy-crisis-2/

- Thomas J. Shepstone, edited version of Clean Energy Crisis on Substack, May 3, 2025: https://open.substack.com/pub/energysecurityfreedom/p/the-clean-energy-crisis-and-why-it?r=kv1a9&utm_campaign=post&utm_medium=email

- Combustion-Engineering History-From Wikiwand: https://www.wikiwand.com/en/articles/Combustion_Engineering_Company Combustion Engineering (C-E) was a multi-national American-based engineering firm that developed nuclear steam supply power systems in the United States. Originally headquartered in New York City, C-E moved its corporate offices to Stamford, Connecticut, in 1973. C-E owned over three dozen other companies including Lummus Company, National Tank Companyand the Morgan Door Company. The company was acquired by Asea Brown Boveri in early 1990. The boiler and fossil fuel businesses were purchased by Alstom in 2000, and the nuclear business was purchased by Westinghouse Electric Company also in 2000. Merger with the Superheater Company During the Great Depression, C-E formed a partnership with the Superheater Company. The Locomotive Superheater Company was founded in 1910 to further the use of superheated steam in locomotives. The Superheater Company’s primary manufacturing facility was located in East Chicago, Indiana. In December 1948 stockholders approved a merger between the Combustion Engineering Company and Superheater Company. Following consolidation the corporation was called Combustion Engineering-Superheater Inc. In September 1950 the firm announced plans to build a large high-pressure generating unit for Virginia Electric & Power Company in Chester, Virginia. In 1953, the name Superheater was eliminated and the company took the more familiar name – Combustion Engineering, Inc. At this time, C-E primarily designed and built boiler assemblies for conventional power plants; those powered by coal and oil. In the mid-1950s, C-E also expanded its operations into oil and gas exploration, production, refining, and petrochemicalswith the acquisition of the Lummus Company located in Bloomfield, New Jersey. Lummus also supplied small industrial steam supply systems for oil field enhanced recovery. C-E was one of the major suppliers of boilers for US Navy steam-powered warships, including Liberty ships during World War II. Amongst many other warships, all of the 46 Knox-class frigates built during the 1960s and 1970s were equipped with a 1,200-pound-per-square-inch (8,300 kPa) C-E power plant. C-E also was a leader in the development of large coal utility steam supply systems which were used worldwide. C-E pioneered the tangential firing process used in modern large pulverized coal utility boilers. C-E maintained a large coal burning test unit at the Windsor, Connecticut site which allowed the Power Systems Group to test changes to boiler air-flow and other critical boiler design factors.

- Nuclear steam supply systems C-E’s nuclear power activity began in 1955 under Arthur Santry Jr. The history of the C-E Windsor, Connecticut campus dates to the early development of the nuclear submarine. From the mid-1950s through the early 1960s, Combustion Engineering, under federal government contract, produced nuclear fuel for the US Navy’s “Nuclear Navy” nuclear submarines. Also located at the Windsor site was the prototype marine nuclear propulsion training facility known as S1C, which was designed and constructed by C-E adjacent to its main campus. The S1C prototype was operated by C-E for more than ten years as an R&D and Naval training facility. After expiration of C-E’s contract, the S1C contract was subsequently awarded to Knolls Atomic Power Laboratory (KAPL), who operated the unit until its decommissioning and dismantlement in the late 1990s and early 2000s. In the 1960s, C-E began selling nuclear power steam supply systems. The first commercial nuclear steam supply system was sold to Consumers Power Company of Michigan for the Palisades Nuclear Generating Station, which closed in 2022. C-E competed aggressively with General Electric and Westinghouse in this domain. In the late 1960s the company supplied nuclear reactor systems and fabricated uranium fuel for electric utility companies. A joint venture was announced in April 1968, involving the Combustion Engineering Company, Houston Natural Gas, and Ranchers Exploration & Development Corporation. The three businesses combined to search for uranium on 250,000 acres (1,000 km2) in New Mexico C-E was generally credited with a superior design, evidenced by the fact that the megawatt yield of its nuclear reactors was typically about 10% higher than that of comparable Westinghouse plants. The basis for this increase in efficiency was a computer-based system called the Core Operating Limit Supervisory System (COLSS) for design, and the Core Protection Calculator (CPC) for real-time control room operation, which leveraged almost 300 in-core neutron detectors and a patented algorithm to allow higher power densities. [citation needed] Combustion also fabricated a number of the Westinghouse reactor vessels and steam generators at its Chattanooga manufacturing facility under contracts with the Westinghouse company. C-E maintained a sophisticated nuclear reactor operator training simulator at the Windsor facility for support for customers of its nuclear steam supply systems…..