This is my Perspective of Proven, Reliable, Affordable & Abundant Energy & Electricity Generation during my lifetime. Here are some of the significant technical advances, changes, regulations, incidents, events and policies that have shaped energy and power generation over the last eight decades. Some personal experiences are interjected during this era just to show where I am coming from in my perspective. Part 2 will cover my thoughts on the impossible transition to renewables.

A Brief History of the Improved Quality of Life Since WWII

Dr. Euan Mearns wrote in WUWT this short summary of the history of energy and the “Energy Transition as Social Vandalism”(19). An excerpt from the concise and well written essay:

“The mid 19th century also saw the development of early internal combustion engines, although at that time there was insufficient fuel for a motor industry. The Spindletop gusher and subsequent discoveries changed all that. The world was now awash with oil without any real market. Then in 1908, Henry Ford rolled out his Model T to begin the age of the car and mass transit. The Wright brothers’ first powered flight in 1908 led quickly to commercial air travel and eventually to the jet age.

Unparalleled development came with the 20th century and the introduction of nuclear power plants whose uranium fuel contains more than 16,000 times the energy content of coal, oil and natural gas. At the same time, hydroelectric power rapidly expanded and natural gas (the most energy dense of the fossil fuels by mass) became more available for electricity generation and home heating and cooking.

The introduction of gas-fired central heating enhanced the well-being of populations. Whole homes would be heated by hot-water radiators, and no longer would families have to huddle round a dirty coal fire. By 2000, life expectancy in world population had risen to 66 years, 78 years in the now developed countries.”

Looking back, I am awed by the progress that was made for the Betterment of the quality of life for Humankind. I am proud of my small contributions along the way.

Some of the Significant Energy & Electricity Mileposts: 1940-2023

- Pulverized coal firing for steam generation becomes the predominant method of power generation

- Mechanical dust collectors are used for collection of particulates

- 1941 B&W invents and develops Cyclone Burners to fire low fusion midwestern coal with more than 70% of the ash collected as a molten smelt

- 1943 Combustion-Engineering invents and develops Tilting Tangential Firing

- Electrostatic precipitators are applied to large coal plants

- 1949 First G-E Gas Turbine for electric power generation in the U.S. installed at Oklahoma Gas & Electric Belle Isle Plant

- 1951 U.S. Navy Admiral Rickover obtains funding from Congress to build the first nuclear powered submarine, Nautilus

- 1953 President Eisenhower’s “Atoms for Peace” initiative

- Supercritical pressure steam generators become common place

- 1955 USS Nautilus puts to sea

- 1955 First “Atoms for Peace Conference” in Geneva

- Steam temperatures and power generation from Rankine cycle steam plant efficiency approaches 40% design efficiency

- 1957 Shippingport Nuclear Steam System, the first U.S. Commercial Reactor is proven

- 1957-59 Philo and Eddystone Ultrasupercritical Units are placed in service

- 1970 – President Nixon signs law to form EPA

- Coal pulverizer state of the art advances to single pulverizers with over 100,000 pounds per hour capacity

- 1973 First Oil Embargo

- 1977 U.S. Department of Energy is formed with the intention to lead America to energy independence

- The Strategic Petroleum Reserve is begun

- 1978 EPA Clean Air Act

- 1978 President Jimmy Carter signs Energy Policy Act

- 1979 Three Mile Island Incident

- 1980 Energy Security Act

- 1988 G-E Single Cycle Aeroderivative Gas Turbine achieves 41.9% efficiency

- 1990 EPA-Clean Air Act Amendment

- 1991-First Horizontal Drilling by Enid Company in OK

- Low NOx Burners or other NOx reduction systems are installed on most coal plants across the U.S.

- Flue gas desulfurization becomes standard for coal plants

- Selective Catalytic Reactors are used to reduce NOx

- 2010 Hydraulic Fracturing combined with Directional Drilling by Harold Hamm’s company greatly increases shale gas production in ND

- 2012 The Shale Gas Revolution produces natural gas at lower cost/million Btu than coal

- 2014 CCGT (Combined Cycle Gas Turbine) units achieve over 60% efficiency

- 2018 G-E CCGT (Combined CycleGas Turbine) Reaches 64% Efficiency

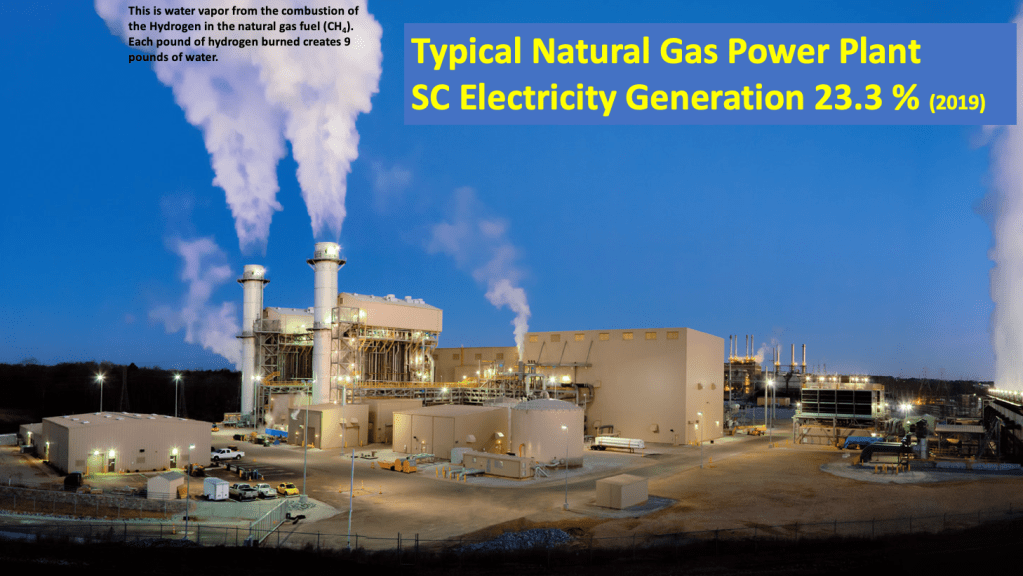

- 2020 Natural gas electricity generation provides over 38% of U.S. electricity production

- 2022 U.S. Congress passes IRA Law and Biden signs, it codifies green energy

Reasonable Cost Energy & Electricity Improves Quality of Life

This is a personal story of electricity generation. Here is my take on how “Living Better Electrically” came to be, during my lifetime. Here is a typical TV ad from circa 1962, the year I entered the workforce.

Electricity Generation 1962-2012 Living Better Electrically

This 50 year period was my personal career, most of which I spent working in the electric power generation business. Including equipment design, manufacturing, startup, testing, operations, maintenance, emissions reduction and upgrading of coal power production equipment. My specialty was large electric utility fuel burning and steam generating equipment. Upon graduation from Williamson in 1962 I was employed as an electrician then as a utility engineer at Mobil Oil Corporation. In 1966 I joined Babcock & Wilcox working in Barberton, Ohio as a Technical Assistant to the Project Engineer in the Nuclear and Special Projects Department. Projects that I worked on as part of the B&W team were the Duke Oconee Nuclear Steam Systems, numerous reactors, steam generators and pressurizers for Navy Nuclear Propulsion Systems and large heavy walled, high pressure, pressure vessels for the Petrochemical industry.

In the 1960’s electricity was very reasonable in cost and nuclear power was proclaimed by the AEC Head (Atomic Energy Commission) Lewis Strauss as soon to be “Too Cheap to Meter”. Commercial nuclear power generation had been proven at Shippingport and was growing exponentially in applications all across the country. The two most memorable engineering leaders that I remember visiting B&W’s Barberton facilities (while I worked there) were Admiral Rickover, the Father of the nuclear Navy and commercial nuclear power generation and Bill Lee, who at the time, was Duke Power Company’s VP of engineering. Mr. Lee was said to have favored the B&W Nuclear Steam System because it was slightly more efficient with the Once through Steam Generator providing a small amount of superheat that competing NSS (Nuclear Steam Systems) did not provide, to the steam supply to the turbine. Duke Power at the time, had commissioned some of the most efficient coal plants in the world and planned to extract the highest possible efficiency from their first nuclear powered steam supply system. This was logical to Mr. Lee and one reason he was attracted to the new B&W OTSG (Once Through Steam Generator) which was designed for a few degrees of superheated steam temperature. My previous blog post discussed the B&W, C-E and Westinghouse nuclear power manufacturing facilities here.

The Most Efficient and Largest Supercritical Coal Power Plants Built 1957-1975

The 1960’s were exciting times for coal fueled power plants too. Two Milestone supercritical power plants were built and started up during this time. The 5,000 psi Eddystone Steam Station (Philadelphia Electric) with a steam generator built by Combustion Engineering and the 4,700 psi Philo Plant (AEP) steam generator was built by Babcock & Wilcox.

Soon after these magnificent accomplishments was the 900 MW Combustion Engineering series of supercritical steam generators at Conemaugh & Keystone plants in western PA. Then the 1,300 MW supercritical steam generators built by B&W for AEP and TVA. Certainly impressive to me at the time with furnaces over 100 foot wide and operation at over 3,500 psi with superheated main steam at 1,000 degrees F. and also Reheated steam supply to 1,000 degrees F.

Duke Power designed, installed, operated and maintained the most efficient coal plants in the world with the additions of Marshall Units 3 & 4 on Lake Norman in 1969 and 1970.

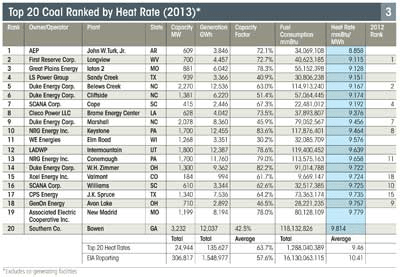

Later, the Belews Creek coal plant was installed and between Marshall and Belews Creek competed for the highest efficiency coal plants in the U.S. Belews Creek Steam Station is a 2.24-GW, two-unit coal-fired generating facility located on Belews Lake in Stokes County, North Carolina. It is or was Duke Energy’s largest coal-burning power plant in the Carolinas and when it was operated on coal it ranked among the most efficient coal facilities in the United States. During 2006, it was the fifth most efficient coal power plant in the United States with a heat rate of 9,023 Btu/kWh (37.8% conversion efficiency). In 2008, it was the #1 most efficient coal power plant in the United States with a heat rate of 9,204 British thermal units per kilowatt-hour (2.697 kWh/kWh) or 37.1% conversion efficiency.

A Few of My Personal Experiences with Coal Plants in the 1970’s

My first foray into S.C. was as one of three startup engineers for the SCE&G Wateree coal plant in Eastover, SC. This is a coal fueled, two unit supercritical steam supply plant which uses two Riley Stoker supercritical steam generators. These are the only two supercritical steam generators built by Riley. They have been very successful and in fact, at this writing are still in service 53 years after the startup of Unit #1. After that in 1972 I was assigned as lead startup engineer at the 420 MW Sutton Unit #3 near Wilmington ,NC. This plant is shown below during steam line blowing in June 1972. Steam line blowing was one of my favorite activities in the startup of a new plant. The roar of the exiting steam at supersonic velocity was memorable and provided a sense of the enormous power of steam. Steam line blowing is a one time startup operation to remove grit and foreign debris from inside the superheater and reheater tubes and piping, so that when operation begins, solid particles of debris will not damage the steam turbine blades.

Following the startup of Sutton #3, in January 1973 I joined Carolina Power and Light Company as a senior engineer. My first assignment was as the lead startup engineer on Roxboro Unit #3. This is a 720 MW coal Unit with a unique design of two half capacity boilers and one common feedwater supply train with a blended single stream steam supply to one G-E 720 MW turbine rated at 2,400 psi 1,000 degree F. Superheat and 1,000 degree F. Reheated steam to the last 13 stages of the turbine. The Roxboro plant is shown below in a recent photo by Duke Energy. This plant was started up as CP&L and was later absorbed to be part of Duke Energy.

Reasonable Cost, Abundant, Reliable and Dispatchable Coal and Nuclear Provide the lowest Cost Electricity in the World

The Roxboro plant is still in operation and it is rated at 2462 MW generation capacity. Let me digress with a short anecdote. Back in the time frame of about 1975 I was involved in an ASME meeting in Niagara Falls, NY. As part of the group, we were given a tour of the Niagara Falls Hydro plant on the U.S. side of the river downstream of the falls. I was struck at the time with the realization that all of the water feeding several of the Great Lakes provides (on the U.S. side) about the same generation capacity as the Roxboro Thermal Plant did. A real world lesson in “Energy Density”. Roxboro’s four units are rated 2,462 MW, the Robert Moses Hydroelectric plant 2,300 MW. This comparison is one I find helpful when non-energy trained people ask why are coal plants necessary? It helps to explain the enormous energy density of a coal fueled power plant.

Fuel Diversity Helps Keep Costs Down, All Fuels Are Important

I joined Riley Stoker in 1969 and worked at Tampa Electric on the final acceptance work of the Gannon Station Units 5 & 6. Then on to the SCE&G Waterree plant for the startup of Riley’s first and only supercritical steam generator. Wateree is still running today and it was very successful. After startup of Wateree #1, I was sent to the City of Lakeland, Florida to finish the startup of the 80 MW oil and gas fueled Power Plant #3 (now named McIntosh) The unique and difficult design of this unit was that it was a stand alone, single unit with no steam connections to another unit. It was fueled by heavy oil, #6 or also known as Bunker C. The oil required heating to about 220 degrees F. to reduce the viscosity for satisfactory atomization and complete burning in the furnace. Because there was no gas or steam connections, the startup entailed firing on Diesel fuel until the boiler had at least 1000 psi drum pressure. Then the stored energy of the boiler would be used to heat and circulate oil from the Heavy oil supply tank. It sounds simple enough, however when the new controls and safety interlocks were all in startup mode, unproven and with numerous glitches, steam pressure would be lost and the operation on diesel fuel would need to be repeated. Any field engineer with experience in oil firing Utility boilers knows the importance of steam or compressed air cleaning of the Ljungstrom regenerative air heaters to prevent fires. That is the reason I was sent to Lakeland. The previous startup engineer was not careful about airheater cleaning and both airheaters were destroyed by fires. I was sent to replace that unfortunate startup engineer.

Oil firing was common in the 1970’s because it was competitive with coal at $0.50/million Btu. After Lakeland I was sent to lead the startup of Jacksonville Electric Authority’s Northside #2. A 325 MW heavy oil fueled boiler. Then off to CP&L Sutton #3, a 420 MW fueled at startup with heavy oil and with provisions for future coal fuel. America’s power demand was rapidly growing, especially in the south where air conditioning and heat pumps were taking off in popularity. As I recall peak load growth was about 10% per year. To illustrate the rapid growth in electric demand, here is my recollection of the units added at CP&L over a five year period:

- Robinson #2, 700 MW, 1970 (Nuclear)

- Asheville Unit #2, 200 MW, 1971 (coal)

- Sutton Unit #3, 420 MW , 1972 (coal/oil)

- Roxboro Unit #3, 720MW, 1973 (coal)

- Brunswick Unit #1, 836 MW, 1975 (nuclear)

During this time period (1970-1977) CP&L was a regional Utility separate from Duke Energy. The total installed capacity of CP&L back during this time was about 6,000 MW. Therefore, the rapid system load growth is illustrated by the addition of five generating units totaling 2,876 MW in generation capacity in just five years. It was a great time to be involved in the power industry… And then came the Oil Embargo and some difficult times for the industry.

During 1973 the U.S. government supported Israel in the Yom Kippur War between Israel and the Arab nations.

At the time of the first oil embargo, 1973-1974, the EPA had been creating needed air pollution rules to reduce emissions from coal fueled power plants. Amongst the first pollutants to be addressed, was particulates. Before the Oil Embargo coal cost and oil cost per million Btus was about the same, right at $0.50 per million Btu. Therefore to reduce emissions fast, Utilities had an economic choice of converting coal plants to oil fuel which has nearly zero ash content or install millions of dollars of backend equipment, including electrostatic precipitators. Carolina Power and Light Company took the path of installing electrostatic precipitators on the newest units (Asheville #2, Sutton #3 and Roxboro #3) and converting the older, smaller coal units to being fueled by oil. Many utilities to the north, including VEPCO, PEPCO, Philadelphia Electric and others, chose the fuel oil conversion route to reduce particulates with less capital cost than installing electrostatic precipitators. This could be done with much lower costs to the consumer because the coal and heavy oil costs were about the same on the fuel cost/million BTU. About $0.50/mmb. Fuel cost is the largest single component of electricity production cost. Comprising between 75 and 92% of the production cost. Thus, when fuel costs escalate, so does the electricity production cost increase.

The Oil Embargo made an immediate fuel supply shortage for all petroleum products and including residual #6 heavy fuel oil. This is when, in my recollections, that major “Wheeling of Power” across state lines became common. The Utilities in the states to the north of CP&L were; VEPCO, PEPCO, Delmarva and Philadelphia Electric. They could receive coal generated electricity from Duke Power, CP&L and other southern Utilities across state lines using existing Transmission interconnections by wheeling power. This was before RTO’s (Regional Transmission Operators) were created.

The 1973-1980 time frame was difficult for Utilities and some had to cut once reliable dividends to stockholders and some went Bankrupt (Consolidated Edison in NY had a particularly difficult time) due to the volatile fuel costs.

National Energy Act of 1978

The energy shock of the oil embargo prompted Congress and the President to act on energy policy. Also during this time the Alaska Pipeline was approved and built(15). Jimmy Carter signed the first Energy Act in 1978.

America’s electricity supply has remained reliable and of reasonable cost for all of my lifetime. Below is a chart of world electricity prices in 2009 which shows the comparison of U.S. electricity prices to other industrialized countries of the world.

Shown on the chart of electricity costs above is Denmark and the Netherlands which were two of the first countries to implement wind farms for significant portions of their power generation.

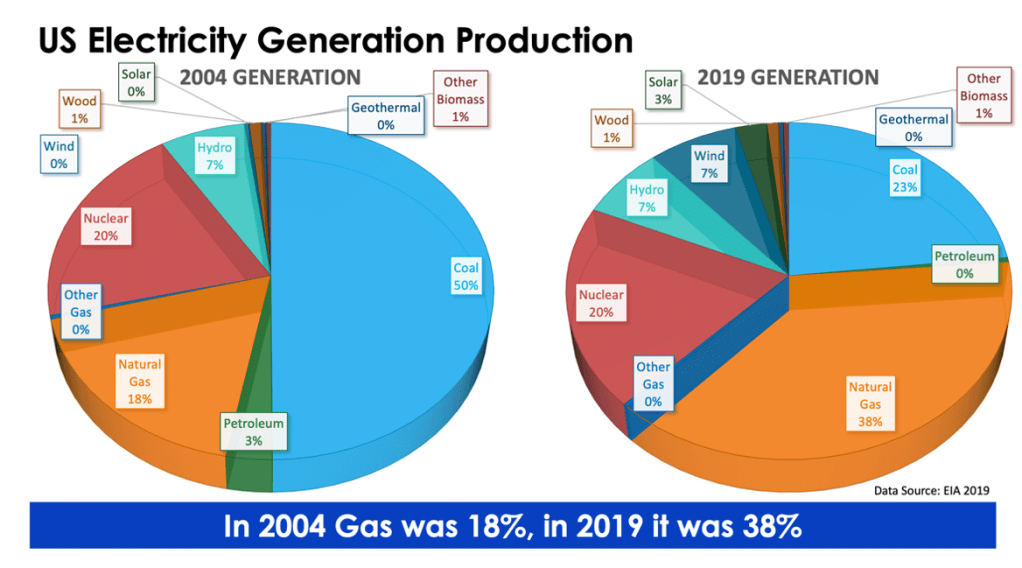

America up to about 2012 used coal fuel for over 50% of our electricity production. Reasonable cost, reliable, abundant and dispatchable coal, generation powered the largest economy in the world. Reasonable cost electricity and GDP tend to parallel each other as shown on the graph below.

Coal Plant Efficiency Rankings

Up until the war on coal, coal plant designers, operators and maintenance personnel took pride in striving for the best overall efficiency. The best yearly coal plant efficiencies were typically from well run supercritical steam pressure units. Duke Power, PEPCO and AEP typically held the top positions. Duke Power’s Marshall and Belews Creek had repeatedly good years. Here is a typical ranking from 2013, Power Engineering Magazine:

I personally remember many meetings with Utility engineering management where the topic of discussion was modifications to the boilers and fuel burning equipment so that fuel changes could be made to reduce the production costs of power and at the same time, reduce emissions. One fuel change that was popular in the 1990’s was to convert coal plants designed for eastern Bituminous coal to fire western Powder River Basin fuel. This reduced emissions of NOx and kept production cost of power reasonable.

The Shale Gas Revolution

The combination of Hydraulic fracturing and Directional Drilling created an enormously large boost in U.S. natural gas production beginning about 2012. Natural gas prices at the Henry Hub dropped from a high of over $12.00/million BTU to about $2.00/million BTU in 2012. This abundance of natural gas fuel at this price, was competitive with well run, efficient coal plants. Then, the E.P.A. ramped up restrictions on coal plant emissions but the consumer was insulated from electricity price hikes because many natural gas CCGT (Combined Cycle Gas Turbine) plants were being built and fuel diversity allowed the Utilities to switch generation from coal plants to new, highly efficient CCGT generating units.

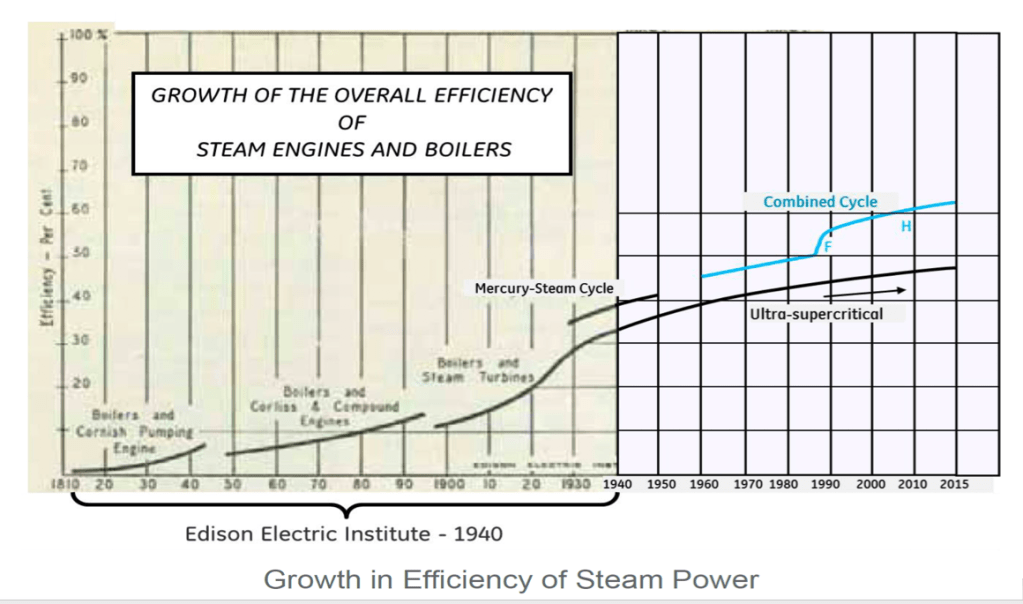

The vastly increased supply of natural gas drove the price of gas down to below the cost of coal on a unit heating value basis. Gas dropped to below $2.00 per million Btu. Also during this time period, gas turbine-combined cycle plant efficiencies increased to the range of 60%. Power generation efficiencies over the years is shown on the graph below. The combination of low cost natural gas and enormous efficiency advantage of CCGT plants greatly increased the use of natural gas fuel for power generation. Keep in mind, the advantage of natural gas fuel is only an advantage when there are pipelines to provide the fuel and there is an abundant natural gas supply. This does not work well in all states, such as Massachusetts and Hawaii.

The combinations of low fuel cost, low Capital cost, low environmental emissions controls cost and greatly increased efficiency together made natural gas fuel more economically attractive than coal for new generating plants. The fuel of choice became natural gas for Utilities that had pipelines and sources of natural gas fuel. Coal fuel accounted for 50% of electricity generation in 2004 but was reduced to 23% by the increased use of more economical natural gas by 2019.

America is Blessed with Enormous Energy and Mineral Resources

America has plenty of Coal, oil, natural gas and nuclear fuels to power our economy and our life styles. I have written other blog posts on the relationship of energy and economic prosperity. Specifically, our lifestyles and our industrial production requires on average, about 315 +/- 15 million Btus of energy each year per person This equates to about 100 Quadrillion Btus of energy per year for our country. This level of energy requirement has held steady for about twenty five years. More on the need for 100 Quads of energy/year are here, here, here and here (20, 21, 22, 23) . Up until the manufactured climate hoax and war on carbon, America enjoyed reasonable cost, reliable electricity and also gasoline, Diesel and Jet Fuel supplies. America became energy independent in 2020.

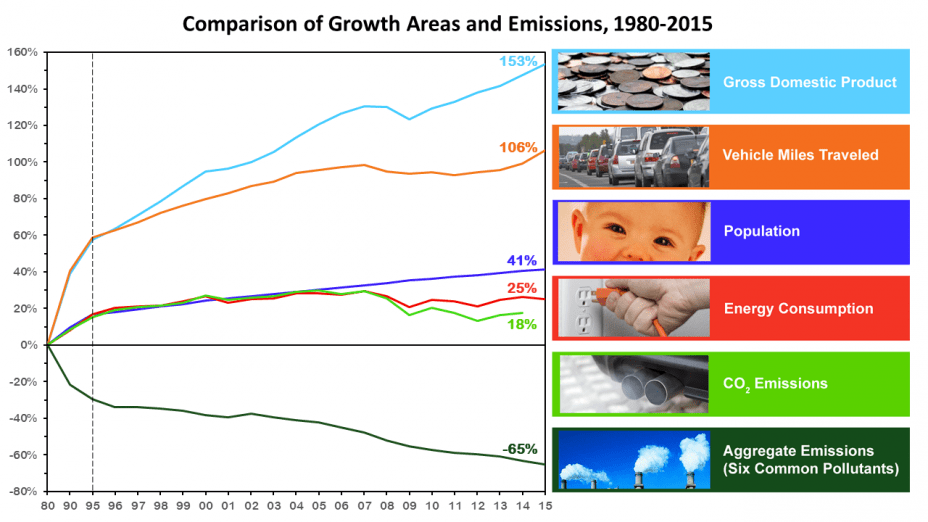

Energy Growth and Clean Air Too!

Protection of the environment is important to all of us, including me. In fact, much of my career was invested in improving efficiency and reducing emissions of coal generating plants. There has been steady progress in cleaning the air and water of the U.S. and I would be remiss if I did not show that during the preceding eight decades in spite of population growth, increases in the number of miles driven and the growth of the economy, the real pollutants have been drastically reduced from the levels of the 1950’s, 1960’s and 1970’s. The chart below was prepared by the EPA.

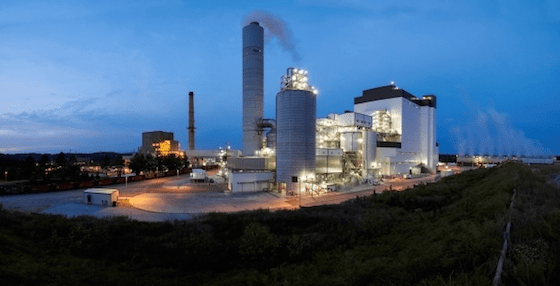

Two of the Last Clean Coal Plants Built in America

Coal plants are robust, reliable and when properly maintained can run safely and reliably for over fifty years. Several of the plants that I have personal experience with were mentioned above. However, newer designs with greater efficiency and improved emission controls should be built to replace the aging plants. In 2008 there were plans for dozens of new, clean coal plants to be built. Two magnificent examples are the John Turk Plant and the (then called Cliffside) #6 Unit at Rogers Energy Center in S.C.

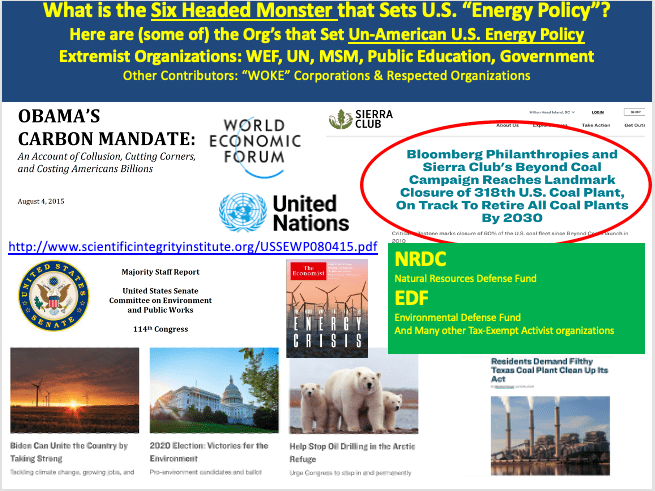

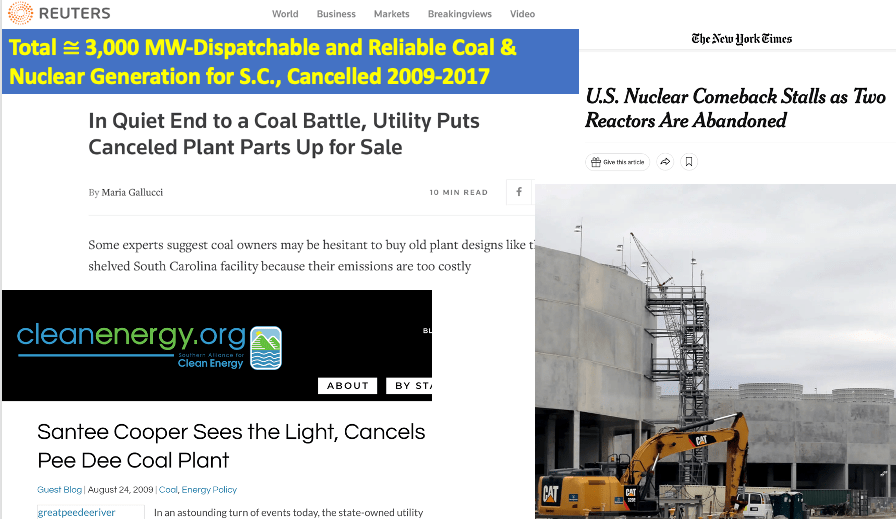

Example of Many New Coal & Nuclear Plants, Planned and Should Have Been Built 2012-2022

The Pee Dee Energy Center is one example of dozens of new, clean, efficient coal plants that were planned but cancelled due to political pressure of the environmental activists. I predict that these plants will be sorely missed during the winter peak power generation periods in December 2023 and January 2024. So will the Summer Nuclear Units #2 & 3 be missed.

Summary

My contribution to the progress made in the last 80 years was very modest and I will quickly admit that. However, because I worked with many talented and visionary engineers and in hundreds of generating plants around the world, I had a very good position to observe the progress of the giants in our industry. Engineers with a Vision of abundant, clean and reasonable cost electricity generation. To mention a few of these giants: Admiral Hyman Rickover, Bill Lee of Duke Power, Mendall Long of CP&L, Bill McCall of Santee-Cooper and many more fine engineers like them. What were their goals? To improve the quality of life, security, safety, economic growth, ensure that reasonable cost power could be produced for decades into the future, provide Bulk Power at the lowest possible cost to attract industry, increase industrial output, provide good paying jobs in their service territory, and design power plants that provide environmental protection for all of the citizens.

During the last 80 years nuclear power became a reality and today about 19% of our electricity is generated from clean, carbon free nuclear power plants. Many are now over fifty years old, but still reliable and inexpensive producers of vital electricity.

Natural gas generation has progressed from the first simple cycle unit built by G-E in 1949 at about 25% efficiency to today’s combined cycle gas turbine plants that at optimum load points can operate at over 60% thermal efficiency. They are amongst the most efficient machines ever built, of any kind.

Ultra-supercritical, clean coal plants such as Turk and Rogers #6 have been developed to provide reliable, reasonable cost, clean and importantly, Dispatchable power generation. There should have been built more like these Why? Because fuel diversity is important when one fuel becomes short in supply. For example, the 1973-74 Oil Embargo. Today most of the Dispatchable electricity generation is from natural gas which of course, flows through pipelines. Pipelines are reliable but, fuel storage is not practical. Coal plants, on the other hand, can store several months fuel supply on site.

Fuel Diversity is important for electricity generation reliability. I am proud to have worked during these years to do my best to make a small contribution to the great progress that was accomplished.

Part 2 will describe the self induced end of reliability, affordability and dispatch ability of electricity generation. As Dr. Euan Mearns recently wrote in “Watts Up With That”….The “Energy Transition is Social Vandalism”(19)

It is my best hope that America and our politicians will wake up and understand the importance of primary energy from conventional sources.

Yours very truly,

Dick Storm, October 4, 2023

References

- You Tube video of a “Living Better Electrically” ad hosted by Ronald Reagan, who was with the G-E Theater on Sunday nights for 8 years 1953-1962: https://www.youtube.com/watch?v=u5Lz1C53RwI

- NY Power Authority Facts on Robert Moses Hydroelectric Plant at Niagara Falls: https://www.niagarafallsinfo.com/niagara-falls-history/niagara-falls-power-development/the-history-of-power-development-in-niagara/robert-moses-generating-station/

- Duke Energy Roxboro Plant Info: https://www.duke-energy.com/our-company/about-us/power-plants/roxboro-plant

- Duke Power Belews Creek Plant Wikipedia: https://en.wikipedia.org/wiki/Belews_Creek_Power_Station

- 1973-1974 Oil Embargo History, Arab-Israel War: https://history.state.gov/milestones/1969-1976/oil-embargo

- 1973 Oil Embargo by Federal Reserve: https://www.federalreservehistory.org/essays/oil-shock-of-1973-74

- Duke Power References of Oconee & Marshall Steam Plant Annual Report 1967: https://www.nrc.gov/docs/ML1526/ML15261A046.pdf

- Power Magazine Feature article on the Top Plant, Duke’s Cliffside #6 which started up in 2013. The last new coal plant I can remember being commissioned for commercial service in the U.S. : https://www.powermag.com/cliffside-steam-station-unit-6-cliffside-north-carolina/

- Scientific American, March 2023, “Seven Ways Jimmy Carter Improved U.S. Energy Future, or At Least Tried to” : https://www.scientificamerican.com/article/7-ways-jimmy-carter-has-improved-americas-energy-future-or-tried-to/

- Power Magazine article on High Efficiency Gas Turbine Developments, 2018: https://www.powermag.com/efficiency-improvements-mark-advances-in-gas-turbines/

- POWER Magazine article on the History of Gas Turbines for Electricity generation: https://www.powermag.com/a-brief-history-of-ge-gas-turbines-2/

- Politico, 2015 article “Inside the War on Coal”: https://www.politico.com/agenda/story/2015/05/inside-war-on-coal-000002/

- Obama’s War on Coal 2008 article in Townhall: https://townhall.com/tipsheet/conncarroll/2014/04/01/obamas-war-on-coal-n1817140

- Explanation of Directional Drilling for Hydraulic Fracturing and production of Shale Gas, Drillers.com: https://drillers.com/directional-drilling-everything-you-ever-wanted-to-know/

- National Energy Act of 1978, Energy Policy Act and PURPA: https://en.wikipedia.org/wiki/National_Energy_Act

- History of the Alaska Pipeline by the American Oil & Gas History Society: https://aoghs.org/transportation/trans-alaska-pipeline/#:~:text=Oil%20was%20first%20discovered%20in,renewed%20in%20November%20of%202002.

- New York Times, May 10, 1974, Con-Edison Declares it may go Bankrupt without help, due to Oil Embargo fuel cost escalations: https://www.nytimes.com/1974/05/10/archives/con-edison-says-it-faces-bankruptcy-without-help-con-ed-says-it-is.html

- Congressional Report on Financial Condition of Utilities, 1970-1986: https://www.cbo.gov/sites/default/files/99th-congress-1985-1986/reports/doc10b-entire_1.pdf

- WUWT, Oct. 3, 2023, “Energy Transition is Social Vandalism” :https://wattsupwiththat.com/2023/10/03/the-energy-transition-is-social-vandalism/

- America Needs about 100 Quadrillion Btus of PRIMARY energy each year: https://dickstormprobizblog.org/2023/05/16/back-to-basics-the-u-s-needs-100-quadrillion-btus-year-of-primary-energy/

- Energy=Life as We Know and Enjoy it: https://dickstormprobizblog.org/2022/08/22/energy-life-that-is-life-as-we-enjoy-it/

- Energizing the Public to Understand the Importance of Primary Energy: https://dickstormprobizblog.org/2023/03/20/educating-and-energizing-the-public-on-energy-policy-and-the-impossibility-of-powering-america-with-wind-and-solar/

- Energy and Economic Prosperity: https://dickstormprobizblog.org/2022/11/18/energy-and-economic-prosperity-2/

- Wake Up America: https://dickstormprobizblog.org/2023/09/21/please-wake-up-america-your-energy-and-electricity-generation-reliability-are-at-risk/

- Dick Storm ENERUM, August 2022 presentation: https://www.linkedin.com/posts/richard-storm-00557810_presentation-and-speakers-notes-from-august-activity-7068650158862827520-B-_W?utm_source=share&utm_medium=member_desktophttps://www.linkedin.com/feed/update/urn:li:activity:7056884647858765824?updateEntityUrn=urn%3Ali%3Afs_feedUpdate%3A%28V2%2Curn%3Ali%3Aactivity%3A7056884647858765824%29