Coal power in America remains important and I wrote on that last week. This is a followup to provide an overview of the importance of coal as a form of primary energy in the rest of the world. The key phrase is Primary Energy.

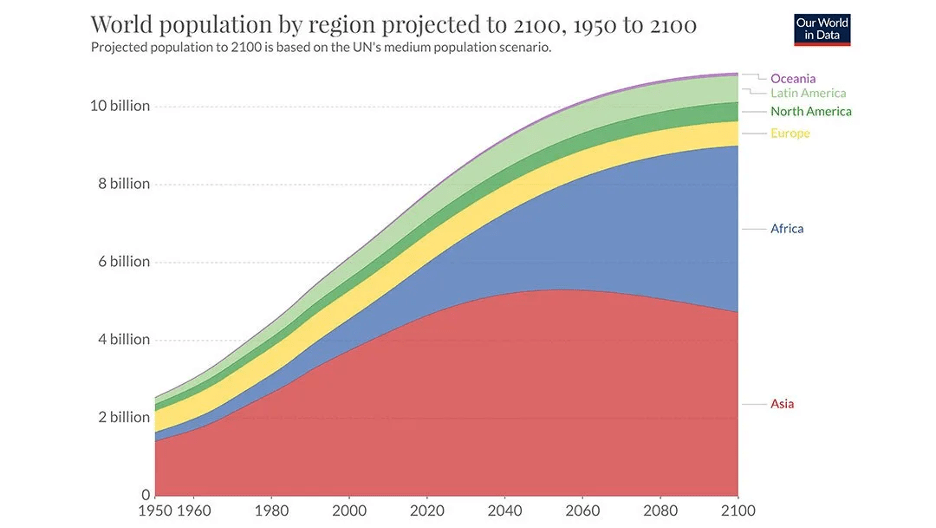

Ron Stein and Nancy Perlman wrote an excellent article on the importance of providing primary energy to the six billion people on the planet that are living in poverty. Lifting them from poverty requires energy, just as energy powered the citizens of countries living in the Developed world.

“In poor countries, millions of those in poverty die every year.

From indoor air pollution from having to burn wood, charcoal, grass, and dung, because they don’t have natural gas, propane or electricity for cooking and heating.

From bacteria and parasites in their water and food, because they don’t have electricity, water treatment or refrigeration.

From malaria and other diseases, because their substandard clinics and hospitals lack electricity, clean water, sufficient vaccines and antibiotics, even window screens. “

It’s disheartening that the wealthier country governments have chosen electricity generation “winners,” i.e., wind and solar, to generate electricity, paid with taxpayer funds, to support the Government Mandates and Subsidies.”

How about India and China?

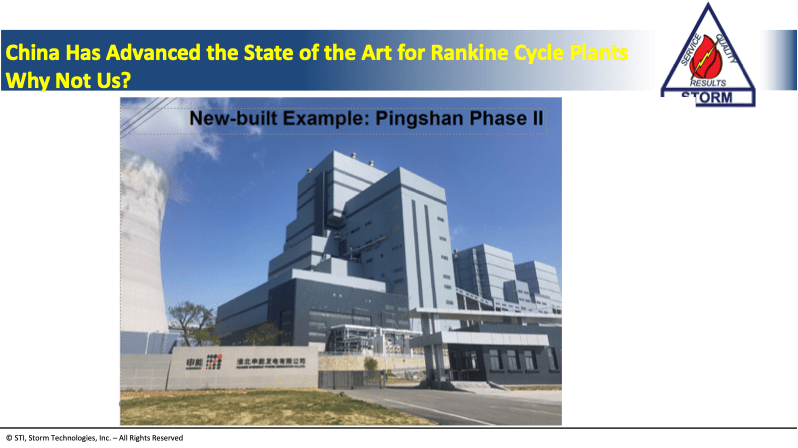

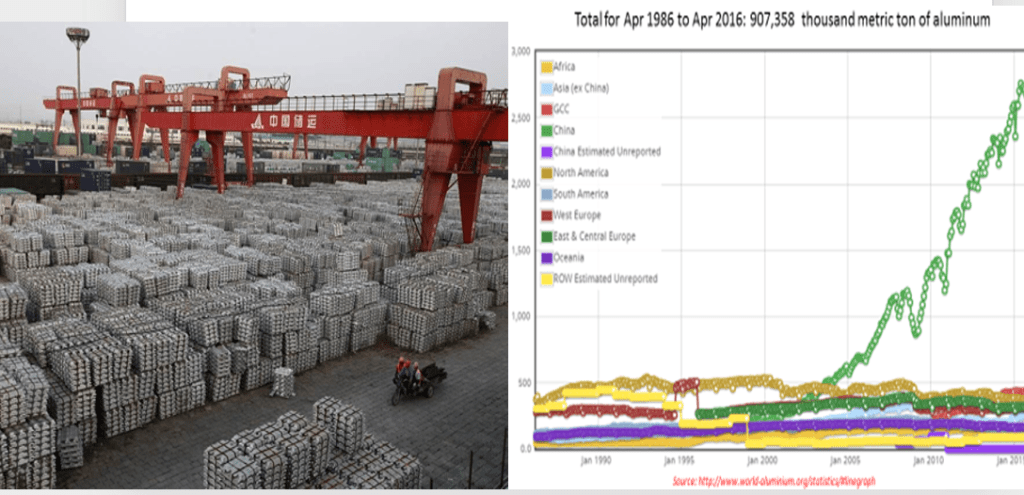

China did in fact lift millions from poverty since they entered the World Trade Organization and became the world’s leading country in manufacturing. One example is their use of enormous amounts of coal as the primary energy to produce aluminum. Before the year 2000 China was an insignificant producer of aluminum. Look what they did in 20 years.

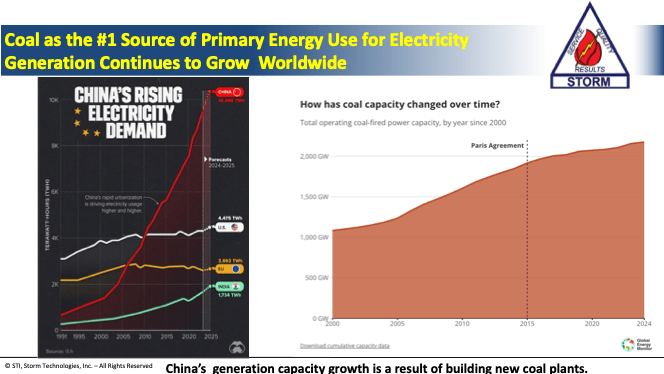

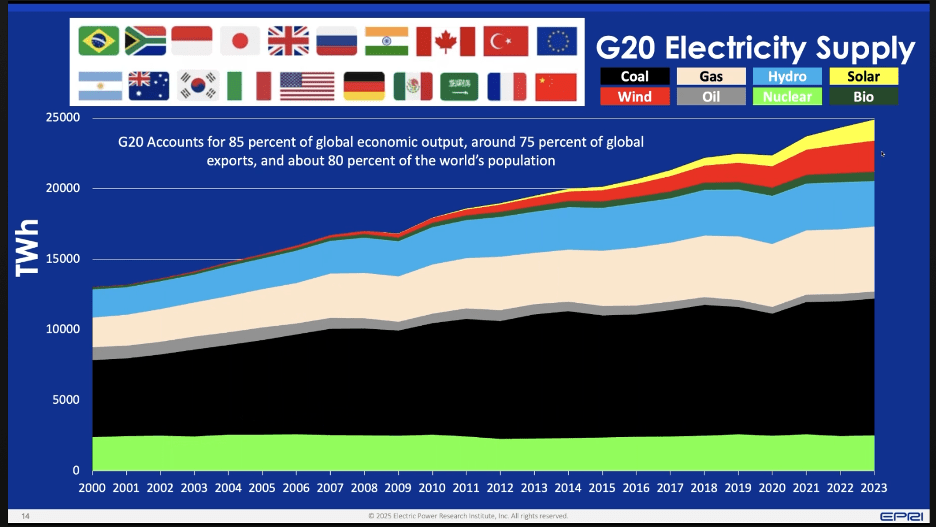

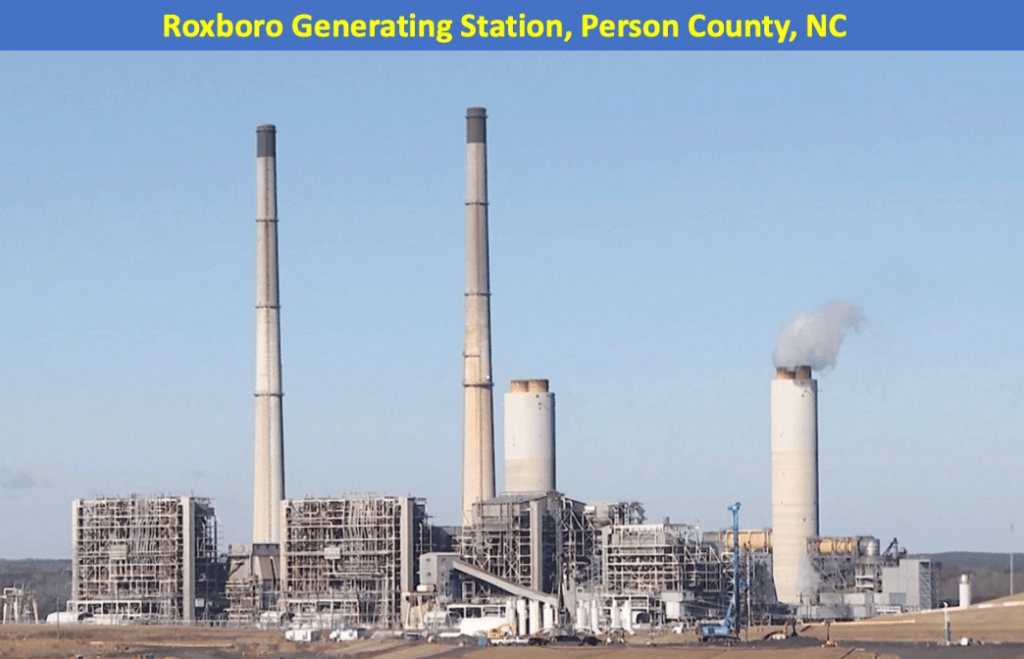

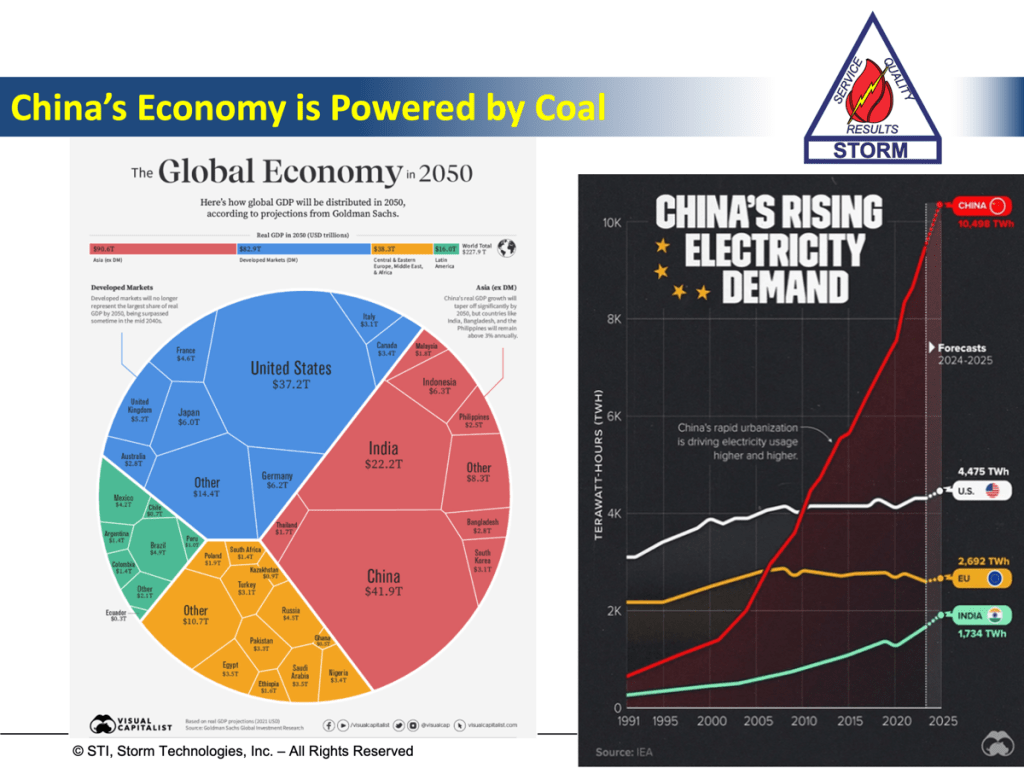

How did China power their economy to become the world’s largest producer of aluminum, steel and most manufactured products in such a short time? They did it with coal power. Thomas Shepstone, Jr. and Duggan Flanigan also wrote about energy intensive aluminum production. Here is an overview of China’s energy production during this period of astounding industrial production growth. This chart below is from my July 2025 presentation to the Coal Institute.

China consumes over 50% of the world’s coal. They understand the sources of primary energy that are viable for affordable, Dispatchable and reliable electricity production, so does India. From the IER (Institute for Energy Research)

“China and India – both considered “developing countries” by the IPCC – are burning record amounts of coal and using more kinds of energy to keep energy prices affordable and increase the standard of living for their people.

Wind and solar energy in China and India are complements, not substitutes, to their massive growth in energy, particularly in fossil fuels.

Fossil fuels provided 82 percent and 88 percent of China and India’s energy, respectively, in 2022.”

How about India, Germany and the UK?

From the Economic Times: “India’s coal consumption could more than double by mid-century before plunging sharply as the country shifts toward cleaner energy, long‑term projections published by government think-tank NITI Aayog show.“

Germany’s path to Net Zero has created much loss of industry. Here are a few references:

WUWT on the Decline of German Chemical Industries due to High Energy Prices, and How Germany is Dismantling it’s Core, by Tilak Doshi.

German De-Industrialization post on the “Last Pipe” from Vallourec Factory.

Lars Shernikau’s blog post on the decline of German Industry due to missteps of Green Policies. Dr. Shernikau is a well respected author and world renowned energy expert.

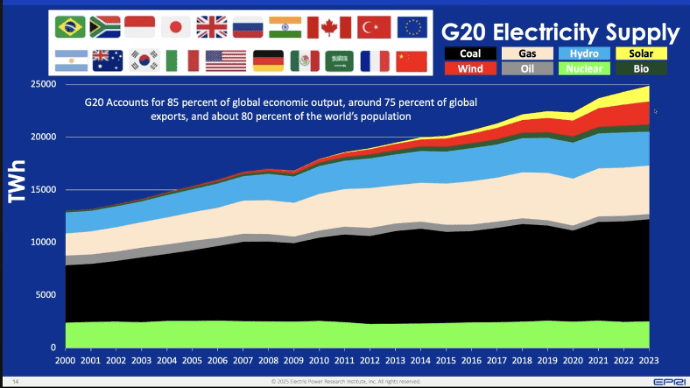

Coal use in the world has steadily increased.

So if Coal Is Such an Obvious Source of Primary Energy, Why is the West Self Sabotaging Their Economies?

I provided a presentation to the ENERUM Energy Forum in Columbus in 2022 to ask this question. A similar presentation to Liberty University in 2023. I am glad to send those presentations. upon request.

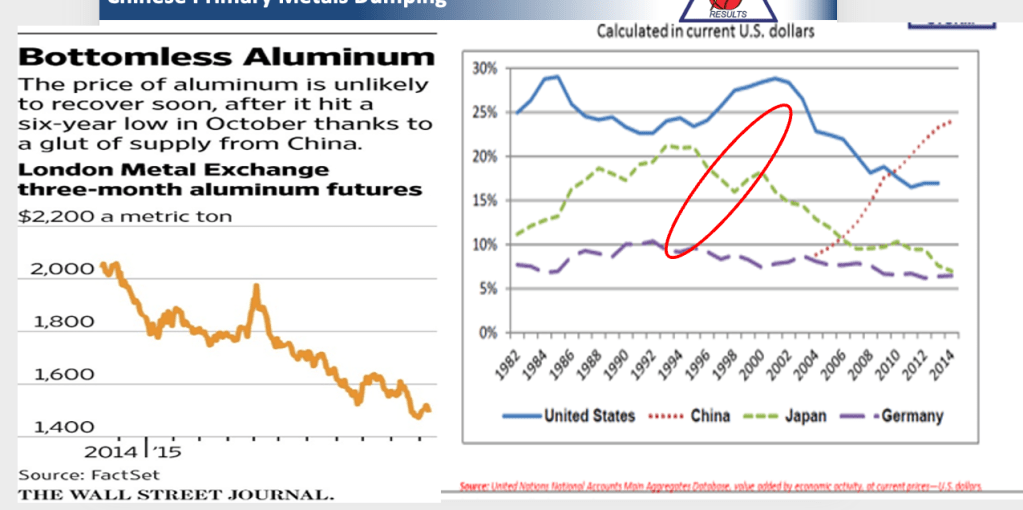

Getting back to aluminum production, here is a graph of U.S. and China production. As America shut down many coal plants and electricity costs rose, China was building new coal plants to provide reasonable cost electricity to smelt aluminum in huge quantities. Many folks, including me believe that China Dumped aluminum on the International markets in lieu of counterfeiting U.S. currency. Note the rise of aluminum produced in China during the years 2004-2014 (from chart above). Both of these charts are from a presentation to the Delaware County Bar Association in 2016 to discuss energy, the economy and how it impacts the Real-Estate Market. Yes, I know that sounds abstract, but reasonable cost energy = jobs, especially for energy intensive industries such as aluminum smelting, then the jobs impact the Real-Estate market.

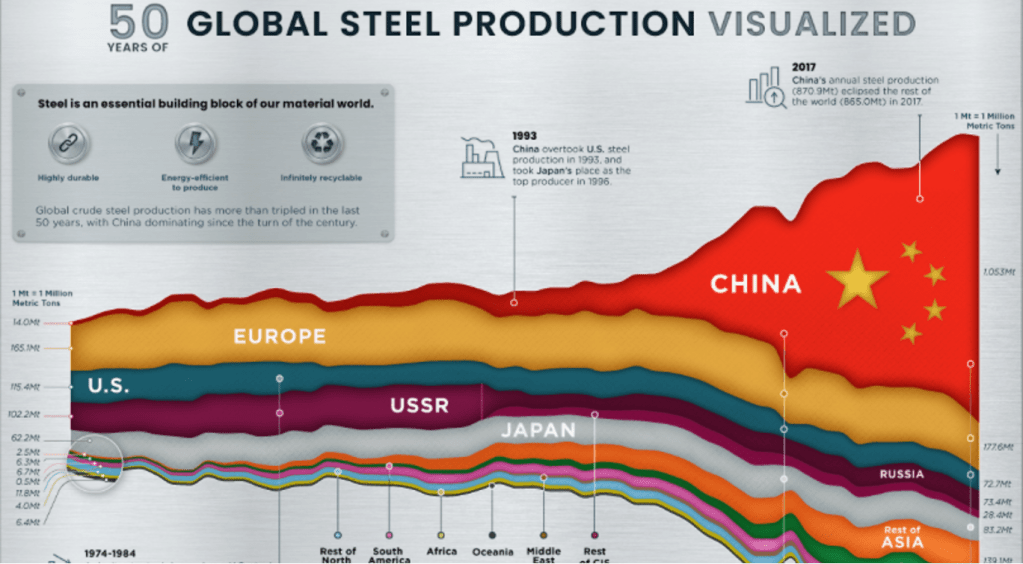

The Self-Sabotaging and excessive environmental laws of the U.S. have not only seriously (I hope not mortally) wounded the aluminum industry, but also steel and heavy manufacturing. Steel production by country is shown below. Why do western politicians continue to do their best to weaken their countries and force manufacturing overseas? It is not only the U.S. it is Australia, Germany the UK and more. President Trump is trying to correct the U.S. problem, but he has much opposition by the Democrats.

The west has been committing energy suicide. Here are links to several articles written by Professor Vaclav Smil, CO2 Coalition’s Gregory Whitestone and Ron Stein. Vaclav Smil for Fraser Institute, “Why Net Zero is Impractical and Unrealistic” and Scam of the Century: Ridding the World of Crude Oil Without a Replacement is Global Suicide”, by Ron Stein and Gregory Whitestone, July 2024. I have also written much with many credible other references on the Self-Sabotaging of the U.S. electric Grid. Here, here and here are three such articles.

Professor Samuele Furfari whom I admire and follow, has written much on the fallacy of hydrogen, wind and solar. Here is a short article he wrote for the CO2 Coalition. Here is an excerpt:

“Over the past ten years, the EU has reduced its energy demand by 6.1 EJ. In contrast, the rest of the world has increased its energy demand by 76.8 EJ – thirteen times more. This is not surprising given that the EU’s competitiveness is currently under threat from the Green Deal. This tragedy is even recognised by the Mario Draghi report, although it does not directly attribute faults to the Green Deal n order to remain politically correct. Instead, the report blames the increase in energy prices, which are nevertheless the consequence of EU energy policy. Outside the European Union, renewable energy sources such as wind and solar power have generated 8 EJ. This figure actually surpasses the change in energy demand within the EU itself. Nevertheless, over the past ten years, fossil fuel consumption has increased by 59 EJ. This means that outside the EU growth in fossil fuels has outpaced that of renewables by a factor of 7.3. In other words, while modern renewable energy is expanding, fossil fuel use is increasing at a rate more than seven times greater. Contrary to the commonly held belief within the EU that the gap between renewables and fossil fuels is narrowing, the reality is that the gap is widening. The evidence suggests that the EU has indeed achieved results in the energy transition, undergoing a profound transformation of its electricity sector and setting benchmarks for renewable energy integration and emissions reduction. However, the EU’s progress is not being matched elsewhere, and its leadership is merely symbolic because the rest of the world is accelerating its use of fossil fuels more than its use of renewable energy. When a leader realises that no one is following them, they must reconsider whether they are truly leading.” I emboldened the line which I thought was most important. It is not only the EU that has chosen the foolish path of Net Zero Carbon, but many other countries and states remain on this course. So, let’s take a look at Australia.

Australia

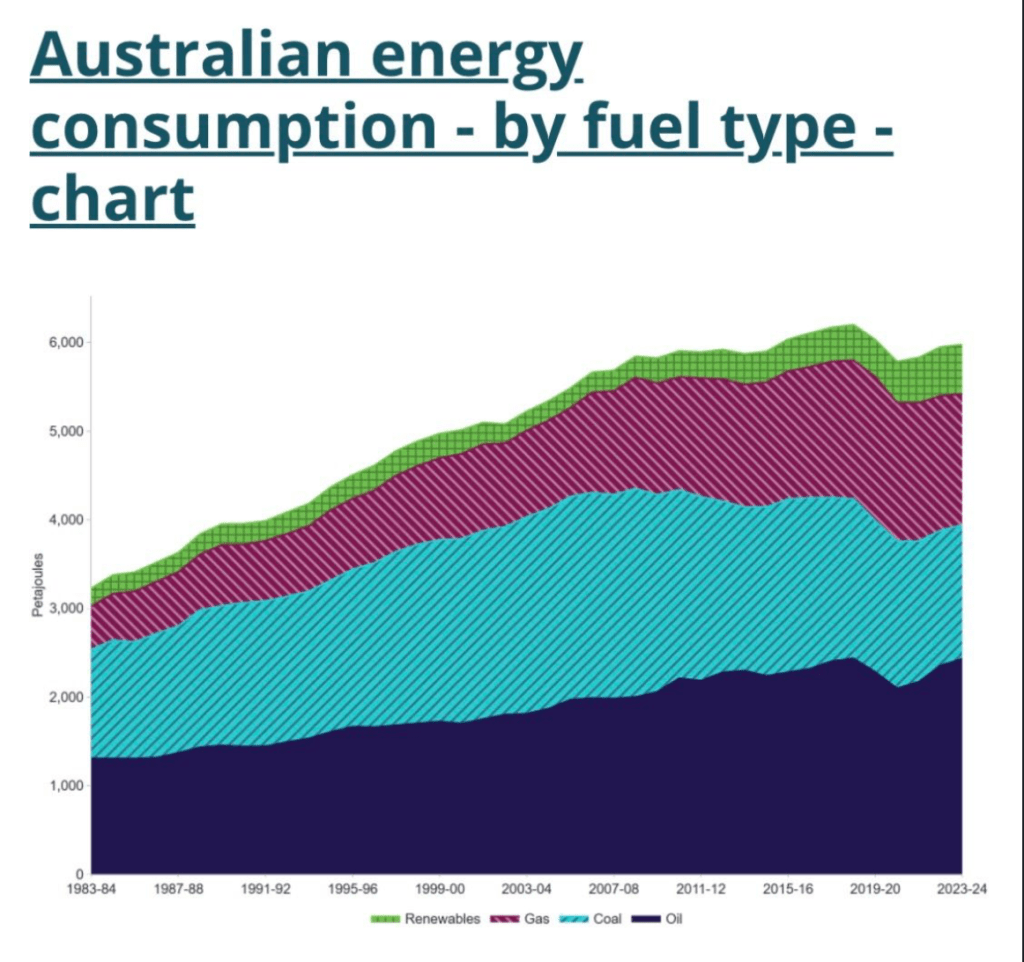

I saw Ben Tan’s post on LinkedIn where he showed the primary energy used in Australia 1984-2024. It is copied below. This shows the constant need for coal power, steady since 1983.

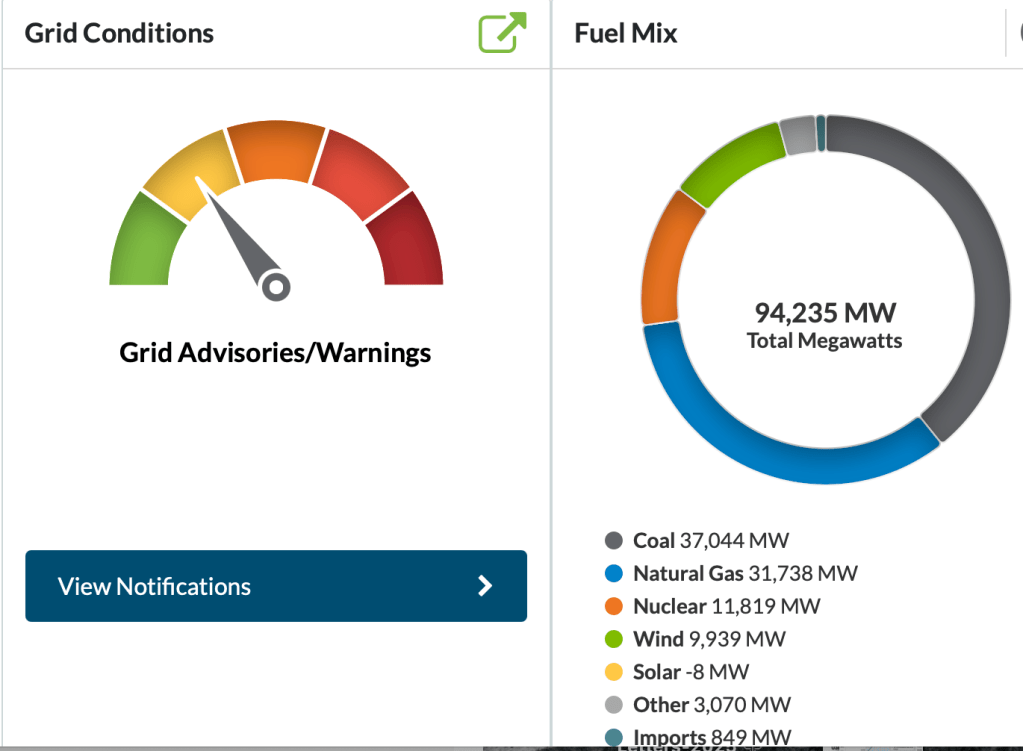

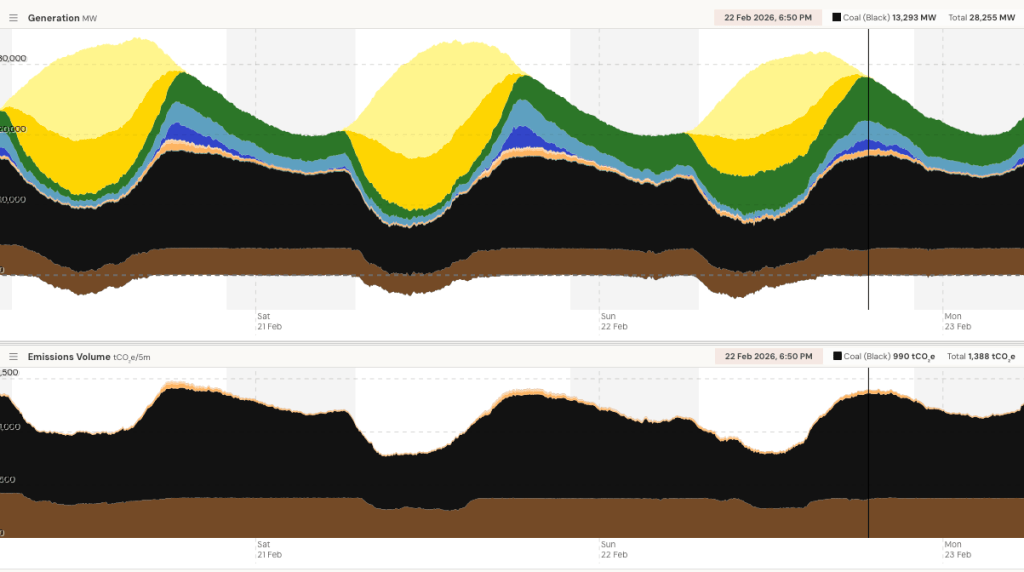

Two other Australian sources for up to date enelectricity generation by source are Rafe Champion and Ben Beattie. I thank them for their articles, links and information. Here below is the Australian Grid generation by fuel for Feb. 22, 2026. Note that it is over 50 % coal. (at one point 38.5% Black coal and 13.2% Brown Coal) Solar and wind were producing 45% at this same moment. Solar does very well during the sunshiny 6 hours or so of the day and wind does well when the wind is blowing, but the voltage control, base load, sudden increased demand requirements (like turning on a 150 MW electric furnace in a steel mill). Also, the rotational inertia and Grid stability are provided by the coal and gas plants.

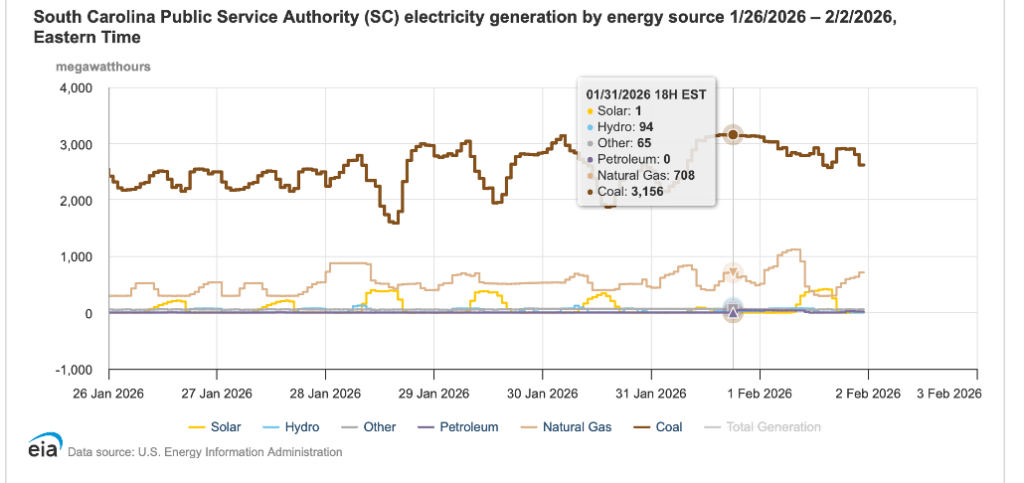

Numerous references are included at the end from Rafe Champion, PA Pundits and others on the problems with wind and solar. Although electricity generation is complicated, it is not rocket science. If the politicians would do just a little bit of reading and research and maybe even ask folks like us that do understand, they could make right decisions. However, across the west politicians insist on weakening their countries. Just like the U.S. presidents Obama and Biden (before President Trump began the Herculean job of correcting anti-American Energy policy) and the German and UK politicians. Of course, even many Bureaucrats and state Legislatures to this day, are still stuck on the destructive path of Net Zero Carbon. Even my Conservative (Red) state of South Carolina. Here is a quote From the Santee-Cooper IRP: “As required by S.C. Code Ann. §58-37-40(A)(4)(c), Santee Cooper has evaluated a Net Zero CO2 “

This reminds me of Charlie Reese’s last column on how a minority of legislators and judges can force their Ideology on the citizens. Off topic but voter energy education and voter turnout needs to be improved. As I said, we even have misguided voters and politicians in the deep red state of South Carolina. We have got to improve the energy IQ of the voters.

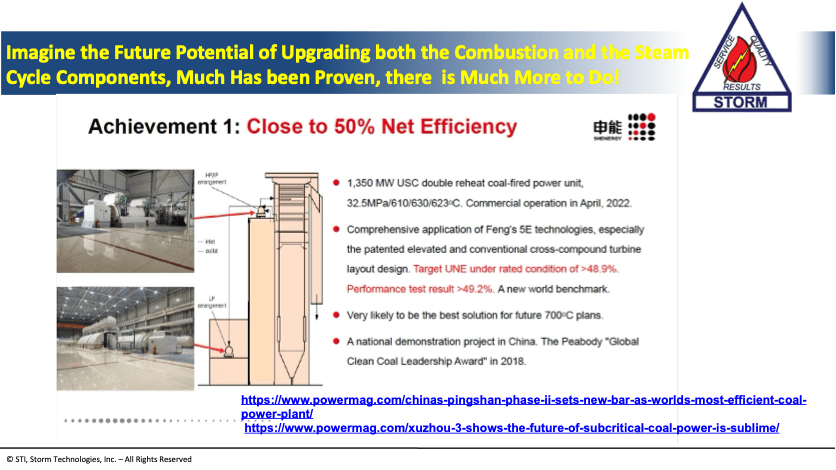

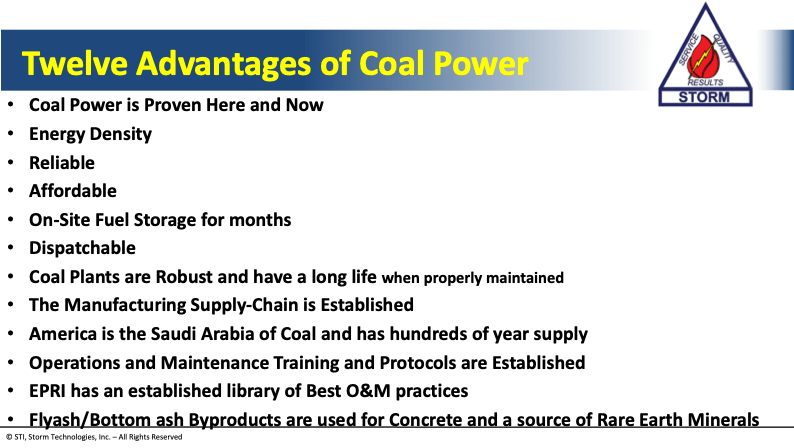

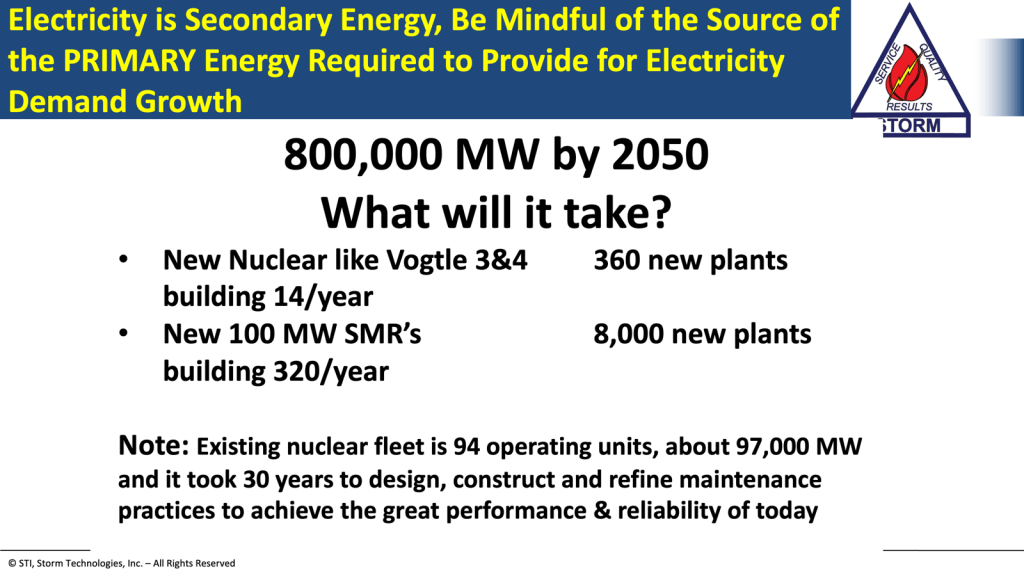

Recent Articles to Support Building New Coal Power Generation Plants

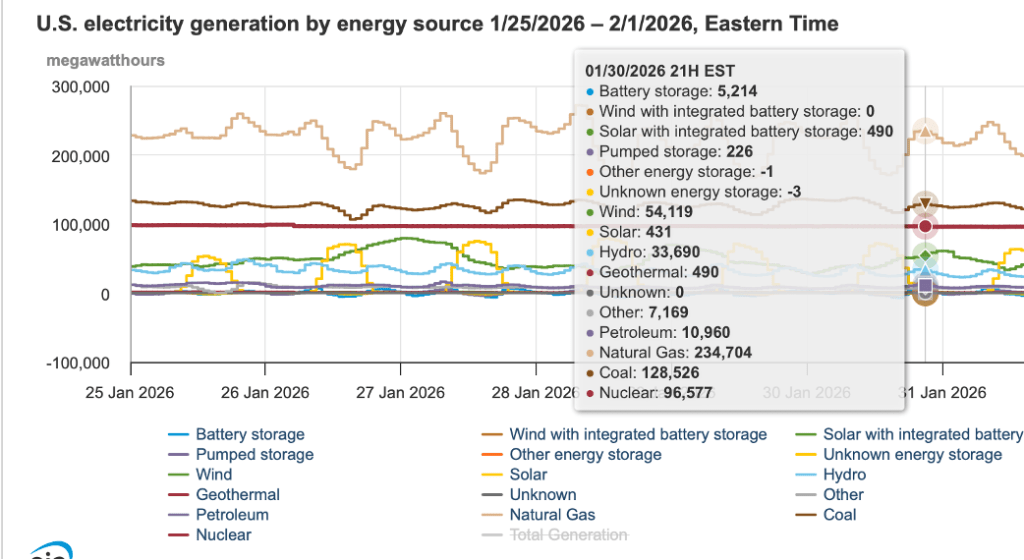

Rather than repeat my same message, here are recent articles I have written in an attempt to explain the case for new coal plants, including two articles on the need to build new coal plants based on coal being the default source of primary energy. The default source of primary energy because the electricity growth is expected to out pace the production of gas turbines to provide for all new generation and nuclear generation, although a very good approach, will take a decade or more to provide the needed electricity generation capacity.

- Ten Hard Truths of Electricity Generation in South Carolina, the Life-Blood of the Economy, Oct. 8, 2025: https://dickstormprobizblog.org/2025/10/08/ten-hard-truths-of-s-c-electricity-the-lifeblood-of-the-economy/

- Reality of Building 32,000 MW of New Generation Capacity/Year. Solutions; Build New Coal Plants Now!, https://dickstormprobizblog.org/2025/10/22/reality-of-32000-mw-year-of-new-generation-demand-solution-build-new-coal-plants-now/

- Power for the U.S.A. Reality of Building 32,000 MW each year: https://powerfortheusa.com/2025/10/22/reality-of-32000-mw-year-of-new-generation-demand-solution-build-new-coal-plants-now/

- Power for the U.S.A. Advantages of Coal Power, Dec. 21, 2025: https://powerfortheusa.com/2025/12/21/advantages-of-coal-fuel-for-electricity-generation/

- 100 Quadrillion BTUs and Why Coal Should be Included in the Primary Energy Portfolio: https://dickstormprobizblog.org/2026/01/28/one-hundred-twenty-quadrillion-btus-and-the-need-for-coal-to-provide-at-least-20-quads-of-americas-primary-energy-part-l/

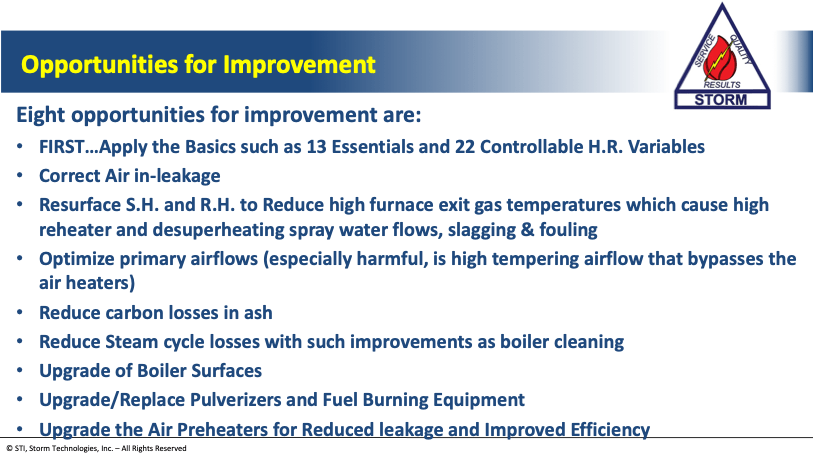

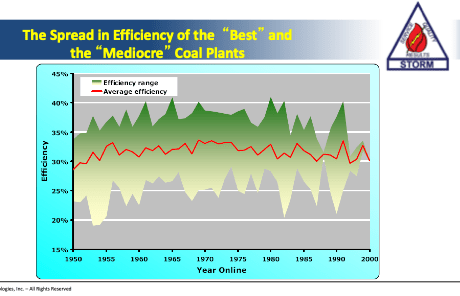

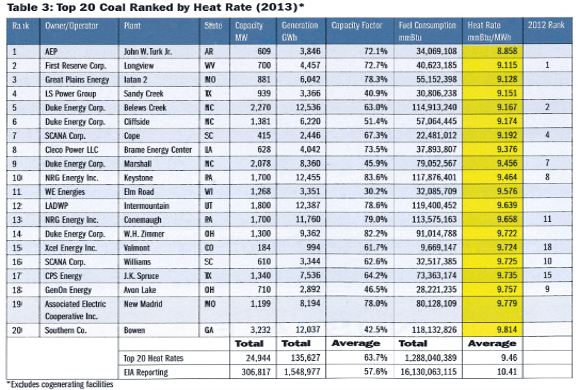

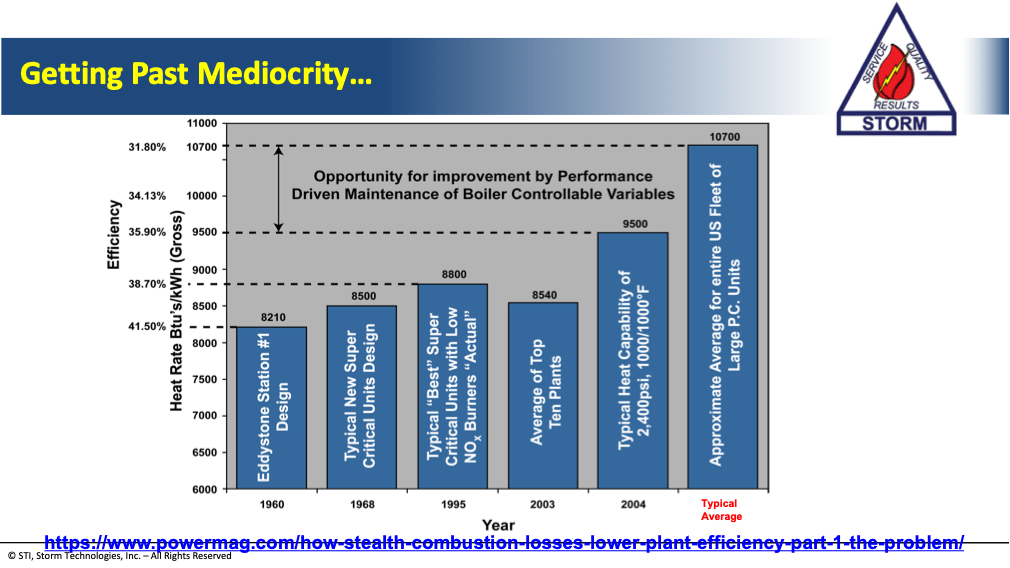

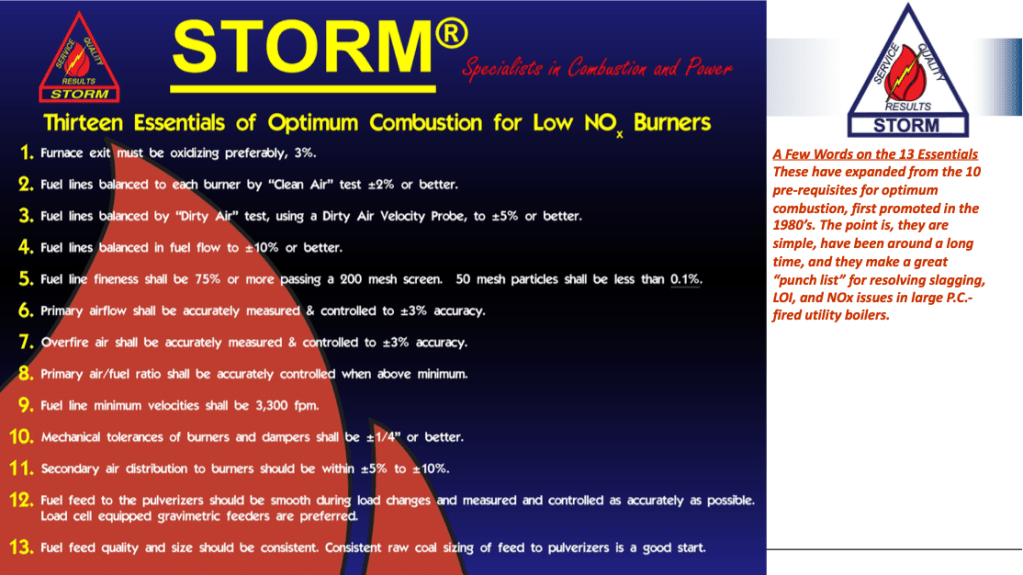

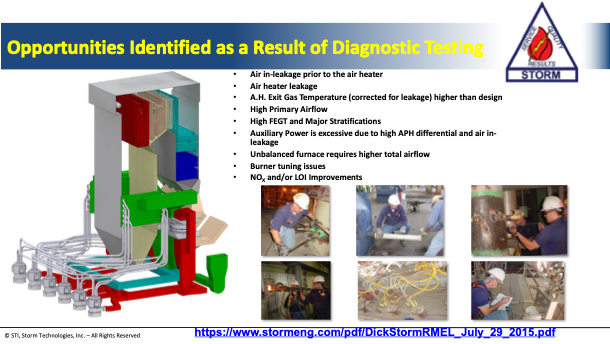

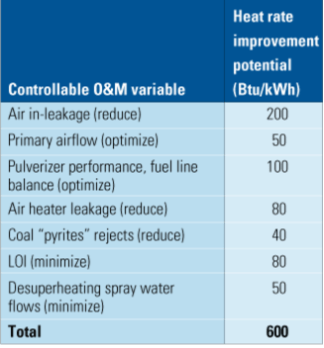

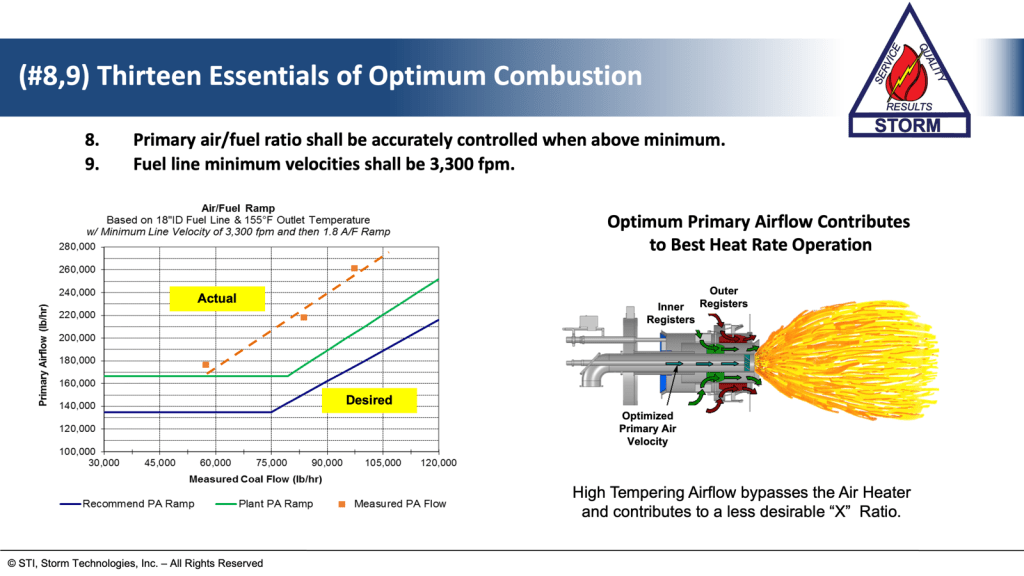

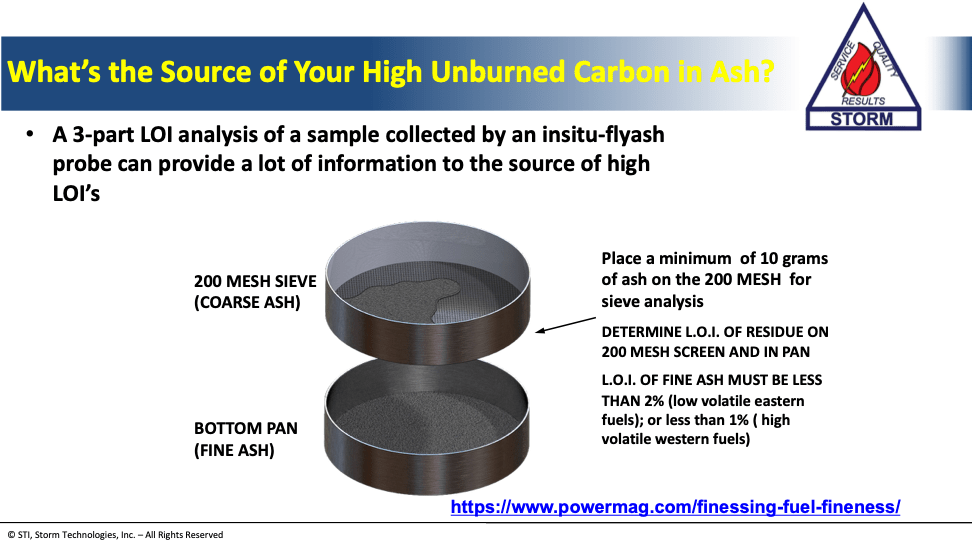

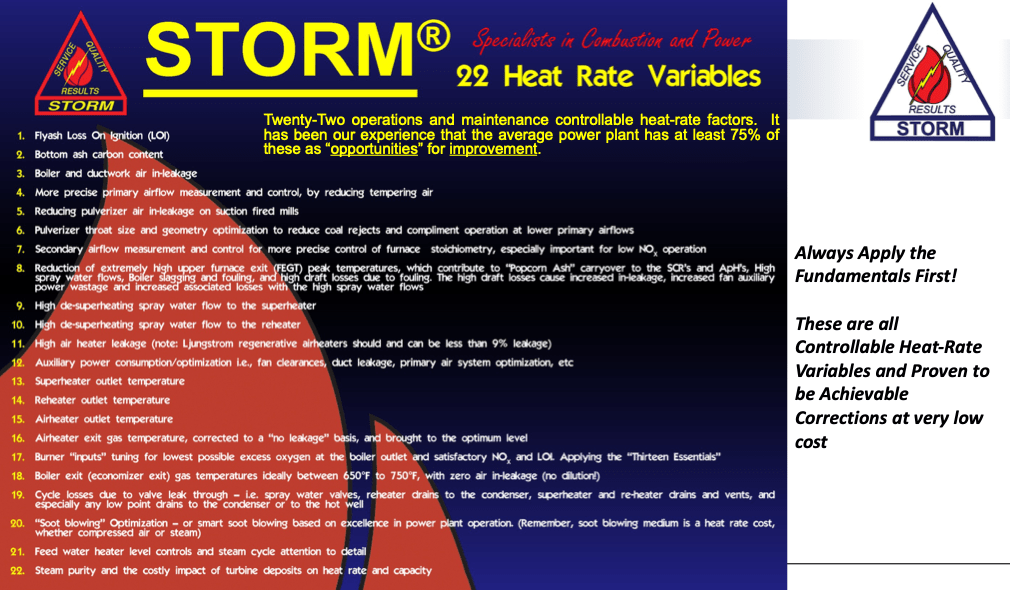

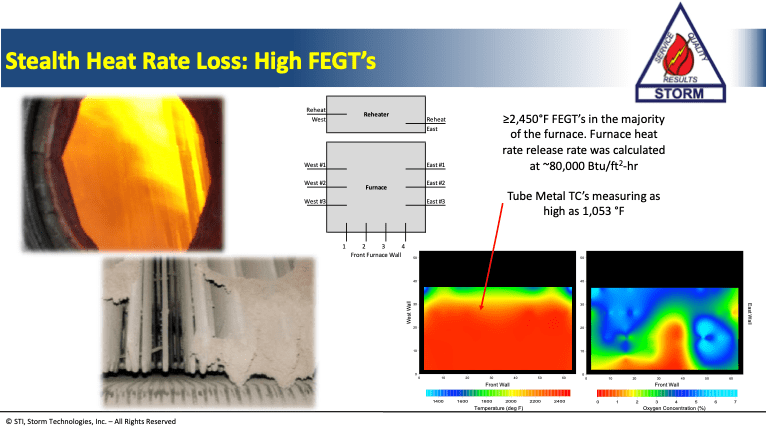

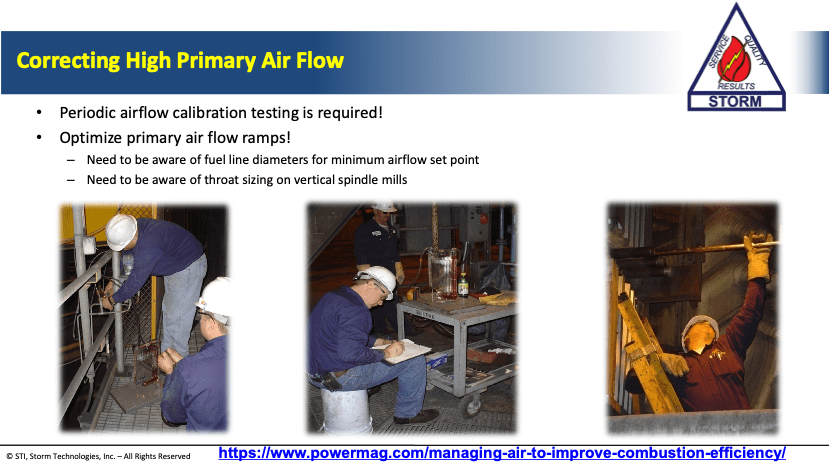

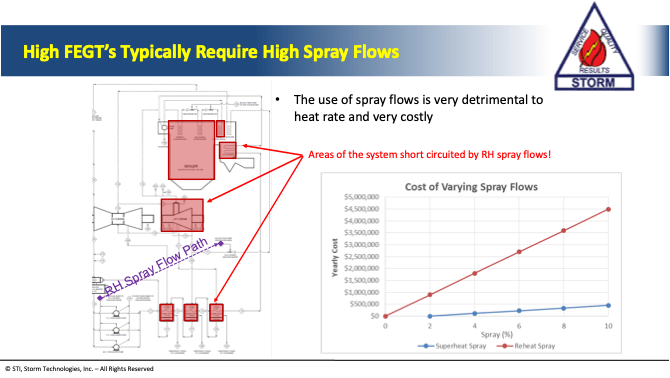

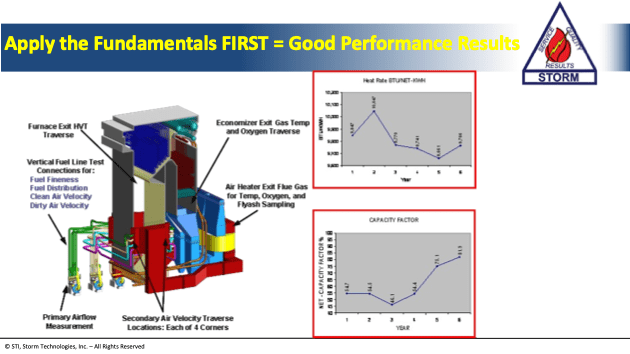

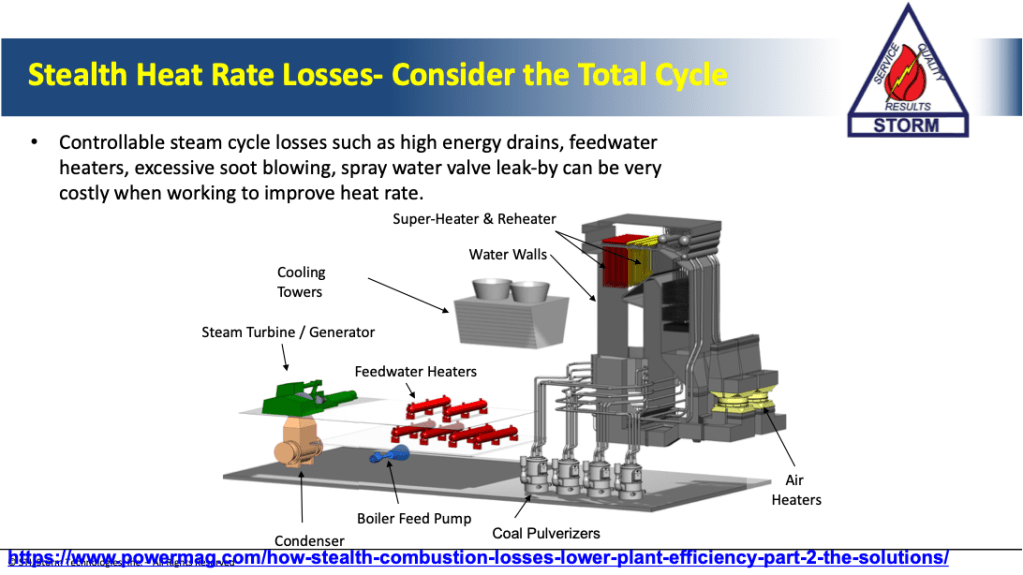

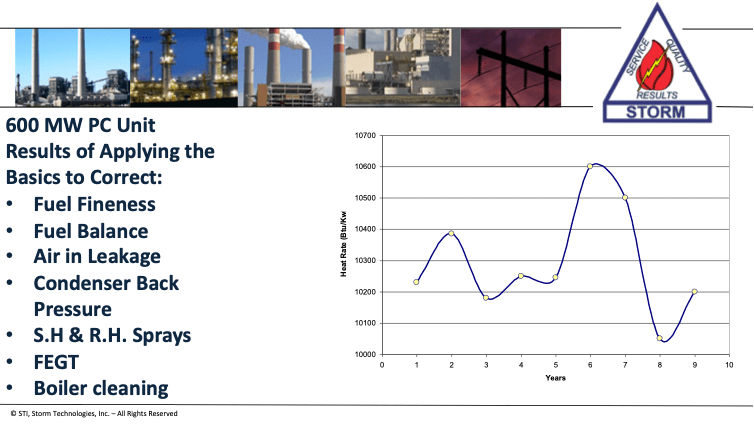

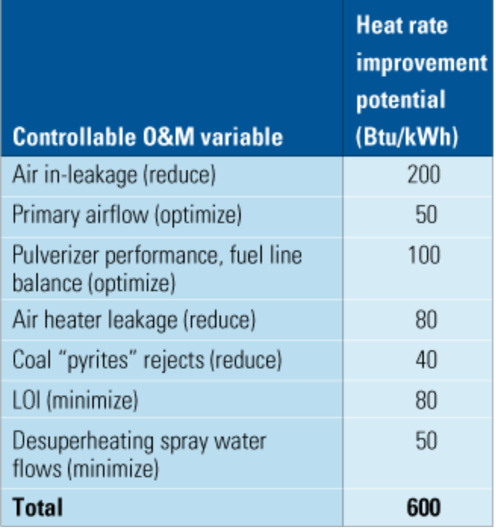

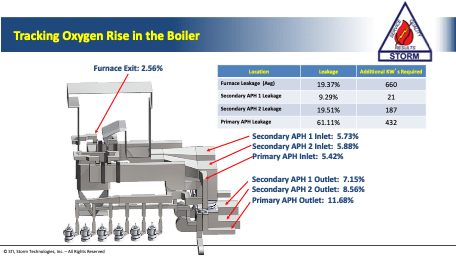

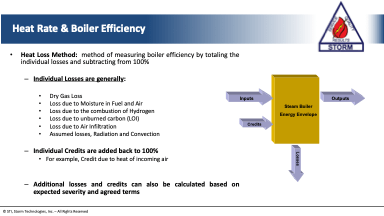

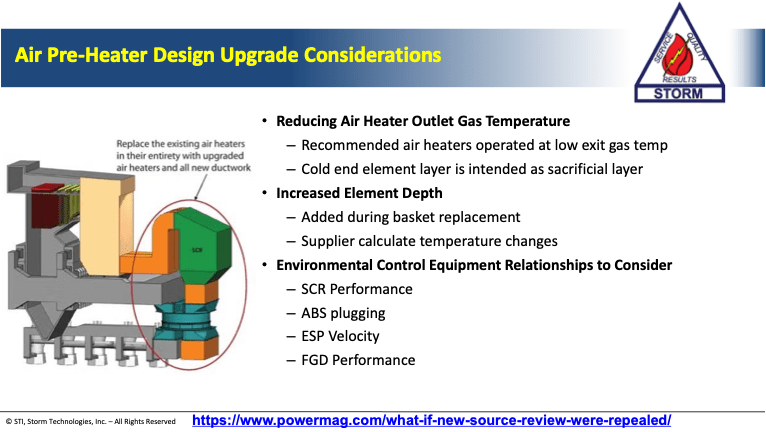

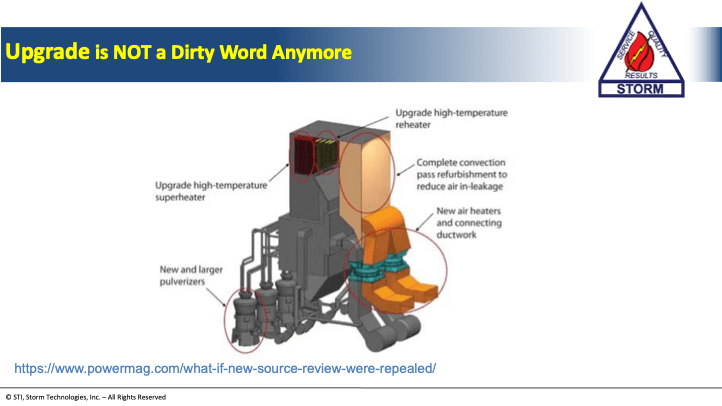

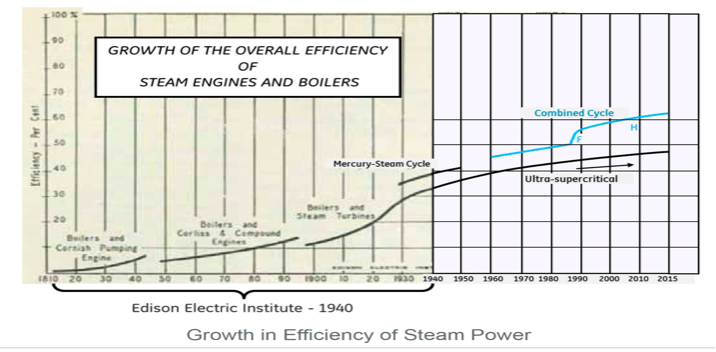

- Dick Storm Presentation to EPRI on the Importance of Applying the Fundamentals for Achievement of the Best Thermal Performance, Feb. 8, 2026: https://dickstormprobizblog.org/2026/02/08/the-importance-of-coal-thermal-performance-considerations-for-heat-rate-and-resiliency/

- Thomas J. Shepstone published version of Dick Storm article on Obtaining Best Performance from Coal Plants, Feb. 2026: https://energysecurityfreedom.substack.com/p/look-at-the-data-the-demise-of-coal

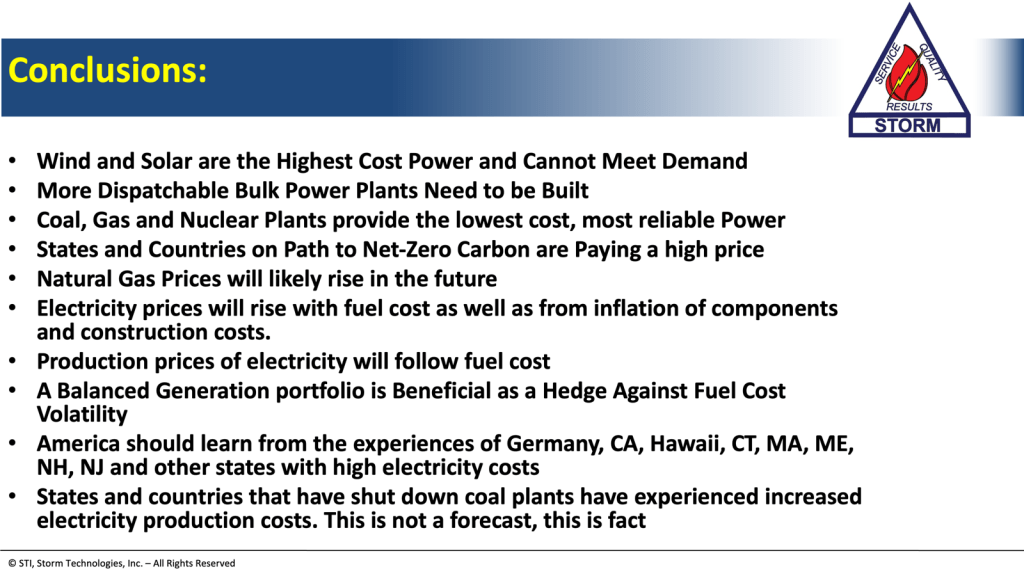

Conclusions

• Wind and Solar are the Highest Cost Power and Cannot Meet Demand, they are a risk to national security and when a region exceeds 30% renewables and the electricity rates are the highest

• More Dispatchable Bulk Power Plants Need to be Built

• Coal, Gas and Nuclear Plants provide the lowest cost, most reliable Power over the long term

• States and Countries on Path to Net-Zero Carbon are Paying a high price

• Natural Gas Prices will likely rise in the future

• Electricity prices will rise with fuel cost as well as from inflation of components and construction costs.

• Production prices of electricity will follow fuel cost

• A Balanced Generation portfolio is Beneficial as a Hedge Against Fuel Cost Volatility

• America should learn from the experiences of Germany, CA, Hawaii, CT, MA, ME, NH, NJ and other states with high electricity costs

• States and countries that have shut down coal plants have experienced increased electricity production costs. This is not a forecast, this is fact

Thank you for reading and

Yours very truly,

Dick Storm, February 22, 2026

References and articles for further research:

- America Out Loud, article: Net-Zero is NOT Affordable by the 6 Billion Living in Poverty: https://www.americaoutloud.news/net-zero-is-not-affordable-by-the-6-billion-living-in-poverty/

- Comparison of China and U.S. Energy Policies: https://dickstormprobizblog.org/2023/01/18/comparison-of-china-energy-electricity-generation-with-u-s-a/

- Duggan Flanigan and Thomas J. Shepstone, Jr. on the energy intensive production of aluminum: https://open.substack.com/pub/energysecurityfreedom/p/trump-is-saving-american-aluminum?utm_campaign=post-expanded-share&utm_medium=post%20viewer

- The importance of Aluminum by the Economic Policy Institute, 2021: https://www.epi.org/publication/aluminum-producing-and-consuming-industries-have-thrived-under-u-s-section-232-import-measures/

- The Aluminum Association: https://www.aluminum.org/PowerUp

- Dick Storm Blog post, “Wake Up Americans!” Sept. 21, 2023: https://dickstormprobizblog.org/2023/09/20/please-wake-up-america-your-energy-and-electricity-generation-reliability-are-at-risk/

- Energy and Economic Prosperity, Talk to Delaware County Bar Association, July 2016: https://dickstormprobizblog.org/2016/07/25/energy-and-economic-prosperity-my-thoughts-dick-storm/

- Thomas Shepstone Published Coal Institute presentation by Dick Storm, July 20, 2025: https://open.substack.com/pub/energysecurityfreedom/p/the-unpopular-but-hard-truths-of?r=kv1a9&utm_campaign=post&utm_medium=web&showWelcomeOnShare=false

- Columbus, Ohio Energy Forum, ENERUM, 2022, Dick Storm presentation: Dick Storm Presentation to Columbus Energy Forum, Columbus, Ohio August 2022: : https://www.linkedin.com/posts/richard-storm-00557810_presentation-and-speakers-notes-from-august-activity-7068650158862827520-B-_W?utm_source=share&utm_medium=member_desktop

- Institute for Energy Research, 2023: https://www.instituteforenergyresearch.org/fossil-fuels/coal/china-and-india-burn-record-amounts-of-coal/

- German De-Industrialization post on the “Last Pipe” from Vallourec Factory: https://www.linkedin.com/posts/activity-7112422447580082176-MMm3?utm_source=share&utm_medium=member_desktop

- “Why Net Zero is Impractical and Unrealistic”: https://www.fraserinstitute.org/studies/halfway-between-kyoto-and-2050

- Scam of the Century, Ridding the World of Crude Oil Without a Replacement is Global Suicide”, by Ron Stein and Gregory Whitestone, July 2024: https://www.americaoutloud.news/scam-of-the-century-ridding-the-world-of-crude-oil-without-a-replacement-is-global-suicide/

- Are You Worried about the Future of America? Jan. 21, 2021 Thoughts on Energy Policies, Industrial and Economic Growth: https://dickstormprobizblog.org/2021/01/21/are-you-worried-about-the-future-of-america/

- U.S. War on Carbon Accomplishes Two Things, Weakens America, Enriches China, Jan. 30, 2021: https://dickstormprobizblog.org/2021/01/30/us-war-on-carbon-accomplishes-two-things/

- Blue Planet in Green Shackles, What is Endangered, Climate or Freedom”: https://wp.me/p5DzAo-nD

- Dick Storm presentation to the Coal Institute, July 2025, Myrtle Beach, SC. Published by Thomas J. Shepstone, Jr.: https://open.substack.com/pub/energysecurityfreedom/p/the-unpopular-but-hard-truths-of?r=kv1a9&utm_campaign=post&utm_medium=web&showWelcomeOnShare=false

- Australia Grid, Real Time: https://explore.openelectricity.org.au/energy/nem/?range=3d&interval=5m&view=discrete-time&group=Detailed

- WUWT on Power in the West by David Wojick: https://wattsupwiththat.com/2025/08/12/electric-power-fantasies-collide-out-west/

- Dr. Samule Furfari on Energy Additions, Not a Transition, Fossil Fuels are the Bedrock of Progress, July 2025: https://co2coalition.org/wp-content/uploads/2025/08/2025-07-Energy-Addition-Not-Transition-Fossil-Fuels-Remain-the-Bedrock-of-Progress.pdf

- The Very Real Costs of the War on Coal, Real Clear Energy, July 2025: https://www.realclearenergy.org/articles/2025/07/31/the_very_real_human_impact_of_coal_closures_1125990.html

- The Coming Electricity Reliability Crisis and the Importance of Coal, Sept. 12, 2024: https://dickstormprobizblog.org/2024/09/12/the-electricity-reliability-crisis-and-the-importance-of-american-coal/

- The Kingdom of Heaven Runs on Righteousness, The Kingdom of Earth Runs on Energy, Oct. 3, 2024: https://dickstormprobizblog.org/2024/10/03/heaven-runs-on-righteousness-earth-runs-on-energy/

- Charley Reese’s Last Column, “545 vs. 300,000,000 : https://dickstormprobizblog.org/2024/11/27/charley-reeses-last-column-a-classic-commentary-written-over-twenty-years-ago/

- Why is Western Civilization Self Sabotaging the Primary Energy that Provides 80% of the fuel for America’s Life-Blood of Reliable Electricity, with the War on Carbon?. : https://dickstormprobizblog.org/2024/12/17/why-is-western-civilization-self-sabotaging-the-primary-energy-sources-that-provide-80-of-the-fuel-for-americas-life-blood-of-reliable-electricity-with-the-war-on-carbon/

- Musings on the Self-Sabotaging Energy Policies and a Reminder of the History of the Rise and Fall of Nations: https://dickstormprobizblog.org/2025/01/13/musings-on-self-sabotaging-energy-policies-and-a-reminder-of-the-history-of-the-rise-and-fall-of-nations/

- The EPA “Endangerment Finding” and why it Needs to Go, Feb. 2, 2025: https://wp.me/p5DzAo-1ZW

- The SWAMP MONSTER vs. 300 Million Americans, Feb. 21, 2025: https://dickstormprobizblog.org/2025/02/21/the-swamp-monster-vs-the-best-interests-of-the-united-states-of-america/

- Thomas J. Shepstone Substack on Dick Storm’s “Primer on How to Ensure Electricity Security (and How to Destroy It)”: https://open.substack.com/pub/energysecurityfreedom/p/a-primer-on-how-to-ensure-energy?r=kv1a9&utm_campaign=post&utm_medium=web&showWelcomeOnShare=false

- Thomas J. Shepstone version of Dick Storm article Feb, 2025. Time to Revoke the Endangerment Finding” : https://energysecurityfreedom.substack.com/p/its-way-past-time-to-revoke-the-pseudo

- Existing EPA-Endangerment Rules Impact South Carolina Electricity Costs and Will Cause Rationing if the EPA Endangerment Finding Isn’t Repealed Feb. 28, 2025: https://dickstormprobizblog.org/2025/02/28/existing-epa-rules-increase-costs-and-will-cause-rationing-of-electricity-in-south-carolina-if-endangerment-finding-is-not-repealed/

- Bjorn Lomberg on the High Cost of Solar and Wind, Climate Change Dispatch, Jan. 2, 2025: https://climatechangedispatch.com/wind-solar-hidden-truth-behind-rising-electric-bills/

- Frazer Institute, “Hot Air, Cold Truths, Bjorn Lomberg, March 2025: https://www.fraserinstitute.org/hot-air-and-cold-truths-bjorn-lomborg

- Delaware County Insider, Wind and Solar are Expensive, Bjorn Lomberg, May 24, 2024: https://delawarevalleyjournal.com/lomborg-the-true-cost-of-wind-and-solar-energy/

- Yahoo Finance and National Post, March 2025, Bjorn Lomberg, Wind and Solar are Expensive: https://ca.finance.yahoo.com/news/bjorn-lomborg-solar-wind-power-100008520.html

- Alabama Attorney General is amongst 22 states in appeal to return to coal for power generation revival of the Grid: https://gulfcoastmedia.com/stories/alabama-attorney-general-calls-for-reviving-americas-energy-grid-with-coal,257548?fbclid=IwZXh0bgNhZW0CMTEAAR0XeLob6rYc5WaBBtSyuB7vHctTdzVhTJxJZ96bExtALJBFoqUPAJPKaY0_aem_8TNpNEKQSIdjNrJTJeBF8Q#//

- Life Powered article on the Unreliability of Wind & Solar in Texas, March 29, 2025: https://lifepowered.org/reliability-standards-to-reduce-the-cost-of-wind-and-solar-volatility-in-texas/

- Joanne Nova on Coal Plant Approvals of the world: https://joannenova.com.au/2025/06/not-dying-global-approvals-of-coal-plants-back-up-to-2015-high/

- Vijay Jayaraj on the importance of energy to Developing countries: https://californiaglobe.com/fr/the-lethal-fog-of-clean-air-hypocrisy/

- Lars Schernikau, “Unpopular Truths” Newsletter on the decline of German Industry due to failed energy policies: https://sh1.sendinblue.com/3gvdip76f0lpfe.html?t=1744529565190

- PA Pundits on Offshore Wind and National Security, Feb. 22, 2026: https://papundits.wordpress.com/2026/02/22/new-book-explores-how-offshore-wind-undermines-national-security/#like-287902

- Future Coal 2025: https://www.futurecoal.org/energy-security-takes-centre-stage-as-global-coal-demand-hits-record-high-in-2025/

- EIA on rising electric prices: https://www.eia.gov/todayinenergy/detail.php?id=67106&utm_medium=email

- WUWT on the Decline of German Chemical Industries due to High Energy Prices, Feb. 4, 2025: https://wattsupwiththat.com/2026/02/04/germanys-chemical-reckoning-how-europe-is-dismantling-its-industrial-core/

- Thomas Shepstone and Robert Bradley, Feb. 4, 2026: https://open.substack.com/pub/energysecurityfreedom/p/tell-republican-rino-we-dont-need?utm_campaign=post-expanded-share&utm_medium=web

- Rafe Champion Substack on Wind Droughts in Australia:

https://rafechampion.substack.com/p/defusing-the-wind-drought-trap - South Carolina Legislation to force Electric Utilities to a path of Net-Zero Carbon:

https://www.scstatehouse.gov/sess124_2021-2022/bills/3194.htm

“As required by S.C. Code Ann. §58-37-40(A)(4)(c), Santee Cooper has evaluated a Net Zero CO2